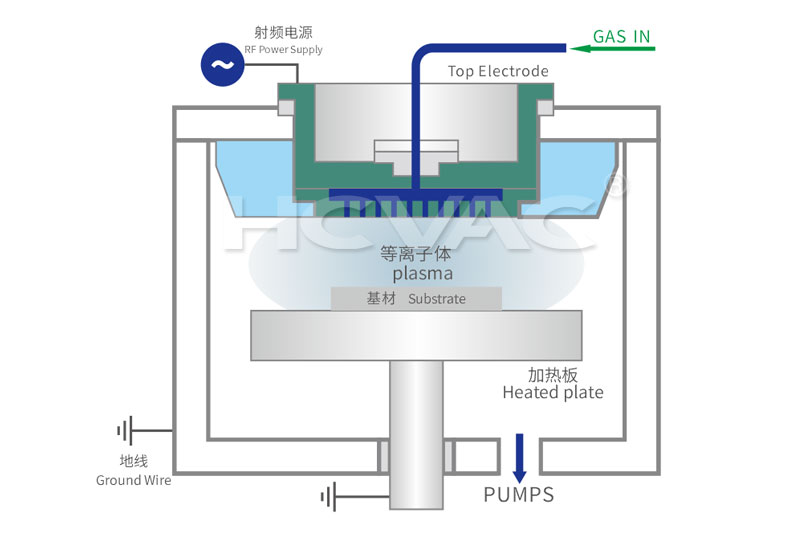

In plasma enhanced chemical vapor deposition (PECVD), the chemical reaction process is assisted by plasma. With the aid of plasma, the process temperature from 200 to 500 ° C is enough to realize the preparation of finished film, so the temperature load of substrate is reduced.

The plasma can be excited near the substrate (short range plasma method). However, for sensitive substrates such as semiconductor silicon wafers, radiation and ion bombardment may damage the substrate.

On the other hand, in the remote plasma method, there is a space partition between the plasma and the substrate. The partition not only protects the substrate, but also allows the activation of specific components of the mixed process gas. However, in order to ensure that the chemical reaction starts when the activated particles really reach the surface of the substrate, the process needs to be carefully designed.

"Low temperature CVD" process is widely used and Huicheng vacuum has many years of experience in this field. PECVD process is an attractive alternative for substrates that cannot withstand high temperatures. For example, the process supports the preparation of functional films on plastic films.

Because the diffusion process at high temperature may damage the doping profile, PECVD coating process is widely used in the semiconductor field. In addition, PECVD process can also be used to prepare polycrystalline silicon, silicon nitride or silicon oxide composite materials for microelectronic devices.

The PECVD equipment of HCVAC can be customized according to the customer's requirements and can be adapted according to the expected process indexes. We also often configure PECVD process module in sputtering equipment to expand technical capacity. HCVAC's competitive equipment price and best equipment quality will surely make you excited.