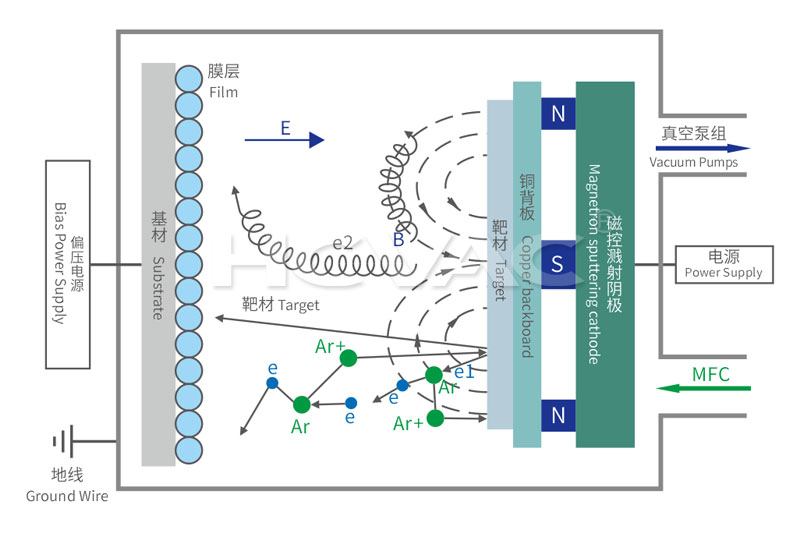

Sputtering is another way of physical vapor deposition technology. The sputtering process is the technology that the target material is bombarded out by ion bombardment. Inert gas, such as argon, is charged into the vacuum cavity. By using high voltage, glow discharge is generated to accelerate the ion to the target surface. Argon ion bombards (sputters) the target material from the surface and deposits it on the workpiece in front of the target. Other gas bodies, such as nitrogen and acetylene, are usually used to react with the target material sputtered out to form a thin compound Membrane.

Sputtering technology can prepare many kinds of coatings, and has many advantages in decorative coatings (such as Ti, Cr, Zr and carbonitride). Because of its very smooth coating, sputtering technology is also widely used in the field of Tribology in the automobile market (for example, CrN, Cr2N and many kinds of diamond (DLC) coatings). High energy ions bombard the target, extract atoms and transform them into gas state. A large number of materials can be sputtered by magnetron sputtering technology.

Advantages of sputtering technology:

+Target material adopts water cooling to reduce thermal radiation

+Almost any metal material can be sputtered as a target without decomposition

+Insulating materials can also be sputtered by RF or if power supply

+It is possible to prepare oxide (reactive sputtering)

+Good coating uniformity

+The coating is very smooth (without droplets)

+The cathode (up to 2m long) can be placed at any position, which improves the flexibility of equipment design

Disadvantages of sputtering technology:

-Lower deposition rate compared with arc technology

-Compared with the arc, the plasma density is lower (~ 5%), the coating adhesion and the coating density are lower

There are many forms of sputtering technology. Here we will explain some of them. These sputtering technologies can be realized on the vacuum coating equipment of vacuum production.

+Magnetron sputtering uses a magnetic field to maintain the plasma in front of the target, strengthen the ion bombardment and improve the plasma density.

+UBM sputtering is the abbreviation of unbalanced magnetron sputtering. The enhanced magnetic field coil is used to enhance the plasma density near the workpiece. A more compact coating can be obtained. Higher energy is used in the UBM process, so the temperature will rise accordingly.

+The closed field sputtering uses the magnetic field distribution to confine the plasma in the closed field. The loss of the target material to the vacuum chamber is reduced and the plasma is closer to the workpiece. A compact coating can be obtained and the vacuum chamber can be kept relatively clean.

+Twin target sputtering (DMS) is a technique for the deposition of insulator coatings. Alternating current (AC) acts on two cathodes instead of using direct current (DC) between the cathodes and the vacuum chamber. This enables the target to have a self-cleaning function. Twin target magnetron sputtering is used for high-speed deposition such as oxide coating.

+Hipims + (high power pulsed magnetron sputtering) uses high pulse power supply to improve the ionization rate of sputtering materials. The coatings prepared by hipims + have the advantages of arc technology and sputtering technology. Hipims + is a compact coating with good adhesion, and it is also a smooth and defect free coating at the atomic level.

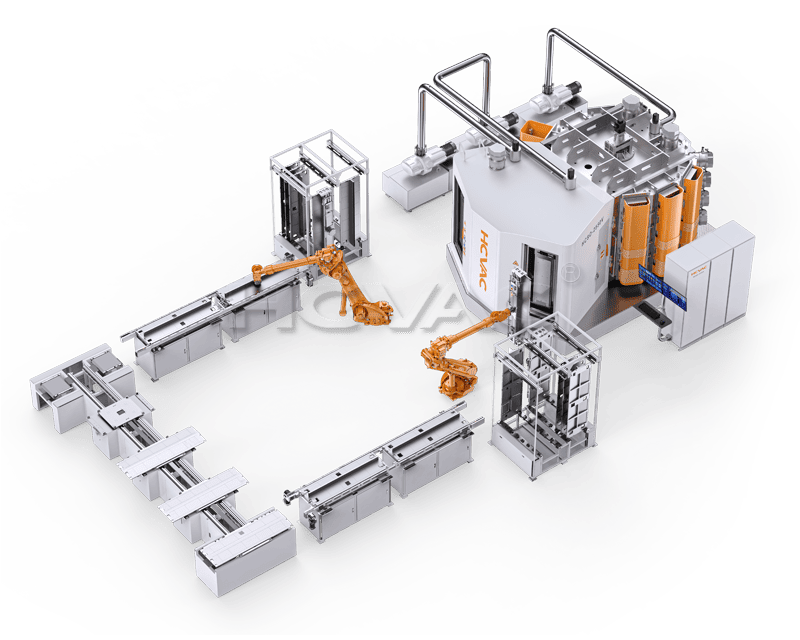

Decorative pvd coating machine can deposit decorative effect coating on the surface of hardware, stainless steel plate, stainless steel tube, glass, ceramics, plastic, acrylic, resin, etc. it has the advantages of simple operation, low cost and large production. It is widely used in jewelry, clock, lighting, kitchen and sanitary ware, construction, medical treatment, catering, scientific research, digital, entertainment, electrical appliances, cosmetics, toys and other industries, and the production after coating Products can show a variety of beautiful effects, such as elegant, dazzling, and the film will not fade for a long time.

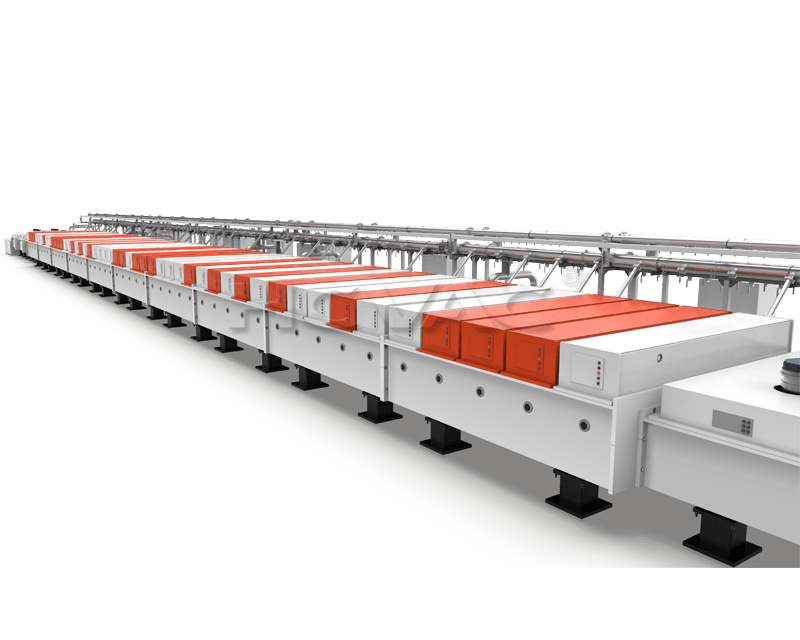

Various kinds of films with optical generation can be prepared to change the transmittance and reflectivity characteristics of the substrate materials they are applied to, such as AR, UV / IR cut-off filter, AF, metal film for motor, hard ar film, enhanced reflection film, hard film, decorative film, ITO film, dichroic mirror, band-pass filter, polarizing tree Grease, RGB filter, photocatalyst, HR film, etc. are widely used in digital cameras, smartphones, glasses, projectors, optical pickups, optical communications, LEDs, electronic products, decorative products, solar cells, displays, etc.

Functional pvd coating machine Based on PMA-I patent technology, HCVAC developed PMA-II patent technology and successfully integrated PMA-II technology into the new generation HCSH coating system. The system has flexible configuration and can be combined with arc, MS, hipims and other technologies to provide more possibilities for the development of new coatings and materials, and is widely used in scientific research, semiconductors, tools, tools, molds, parts, medical devices, optics, new energy and other industries.

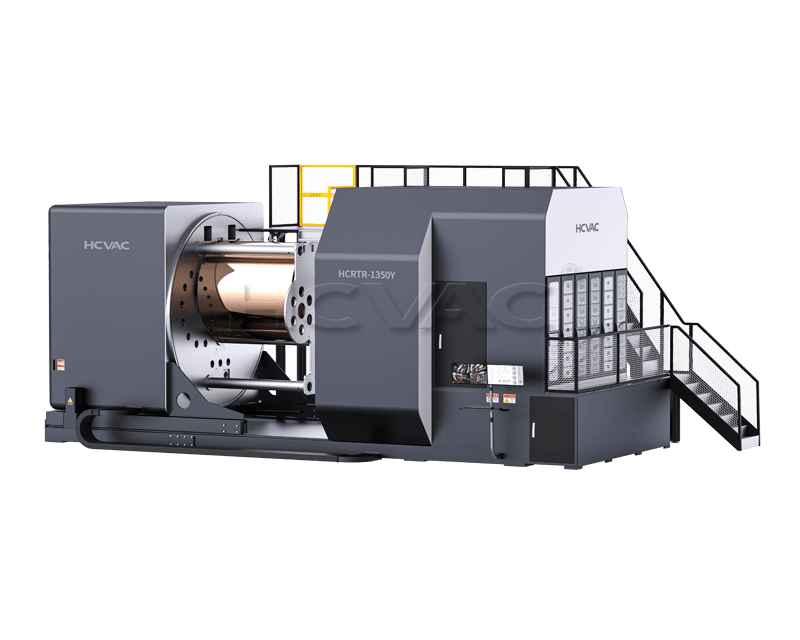

PVD technology of magnetron sputtering or evaporation is used for continuous coating on strip substrate. Magnetron sputtering can be used for continuous coating on strip coil surface such as pet, PI, PC, cop, other flexible polymers and metal strips. It can be used for aluminum, titanium, chromium, copper, nichrome, nickel, silver and other metal materials, TiO2, Nb2O5, SiO2, ITO, sialox, MoOx and other nitrides or oxides. Evaporation can be used for continuous coating on pet, (b) OPP, PVC, CPP and other macromolecular films, paper, metal foil, aluminum, copper, silver and other metal materials, ZnS, SiO, MGF and other compounds.

HCVAC provides vacuum coating machine or pvd coating machine and process applied to auto lamp or interior lighting industry parts, interior trim, etc., such as auto headlight and tail lamp, auto rearview mirror, car logo, car grid, door handle, door and window light strip, interior trim strip, interior lighting, etc. This series of equipment is equipped with plasma treatment device, high-efficiency magnetron sputtering cathode and resistance evaporation device, etc. the deposition rate of the equipment is fast, the coating adhesion is good, the coating is fine and dense, the surface finish is high, and the uniformity is good.

It is mainly used for plating high-quality, high-performance metal film, electromagnetic shielding film, reaction film, composite film, transparent conductive film, antireflection (AR), antireflection film, Low-E film on flat glass, acrylic, PC, pet and other surfaces. The company can provide design, complete equipment, process and "key" engineering services according to user requirements.