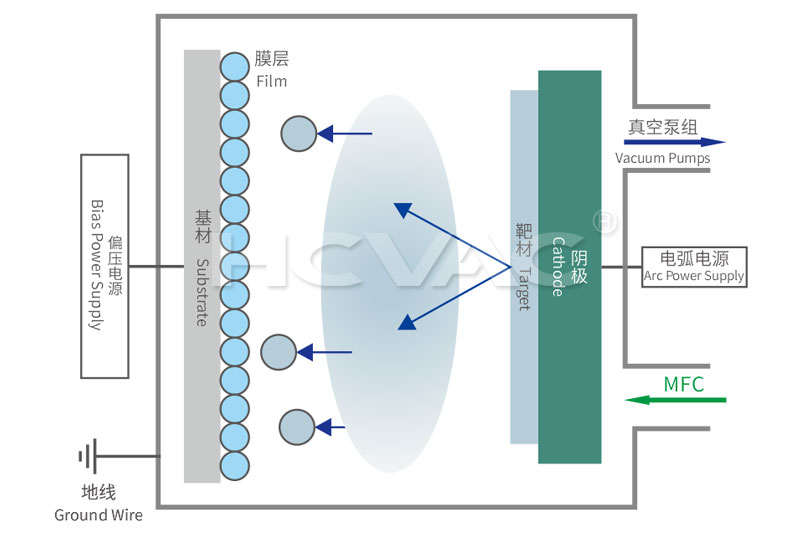

PVD is the abbreviation of physical vapor deposition (PVD). It refers to the technology of vaporizing material (commonly known as target or film material) into gaseous molecules, atoms or ions under vacuum conditions, and depositing them on the workpiece to form films with certain special functions. The common PVD deposition technologies include evaporation technology, sputtering technology and arc technology.

Ion plating technology is a kind of PVD technology, which means that in the process of PVD deposition, the metal or non-metallic plasma (such as Ti ion, N ion) is formed by the plated material, and the plasma is deposited on the workpiece surface under the action of bias voltage electric field. In the process of ion plating, the ion energy is stronger, the ion diffraction is better, the adhesion force of the film is better, the density of the film is better, and the performance of the film is better.

Ion plating technology is widely used, including decorative coating, hard coating of tools and moulds and various functional coatings.