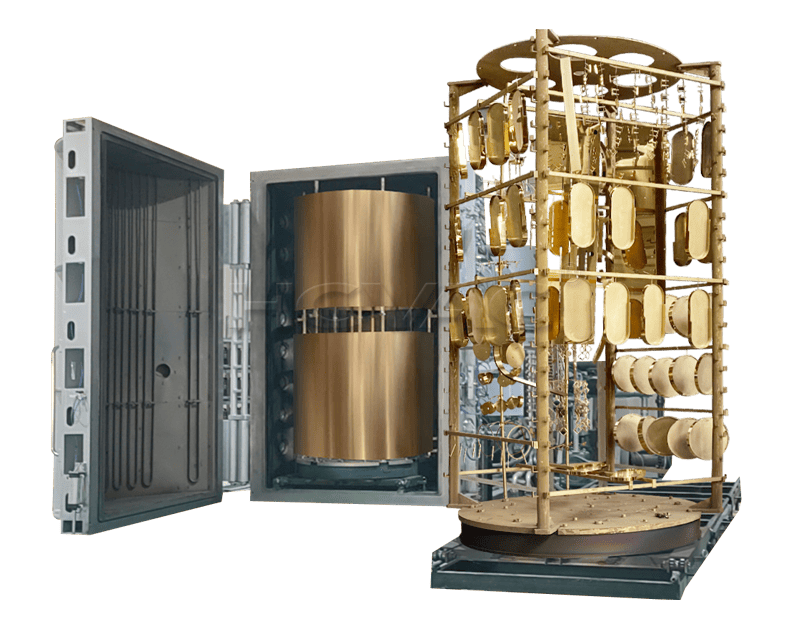

---For Large Sheet, Pipe & Part Coating

This machine, featuring a vertical side-door design, is designed for coating stainless steel sheet, pipes (up to 6m), display racks, logos, locks, handles, bathroom hardware, utensils, plastic parts, ceramics, and more.

It offers coatings like TiN titanium gold, TiC gun black, ZrN gold, TiCN rose gold, and TiO sapphire blue, among others.

It is safe, environmentally friendly, process-stable, color-rich, and provides excellent abrasion, corrosion, high-temperature resistance, and long-lasting adhesion.

Key Features of Vertical Side Door Decorative PVD Ion Plating Machine

Precise parameter control and consistent coating process

Multi-color, uniform, and vibrant finishes

Spacious cavity, fast process, user-friendly software control

Reactive technology with high ionization and plasma density

Remote diagnostics for efficient support

Eco-friendly, pollution-free production

Arc ion coating machine is a high-efficiency, environmentally friendly, and pollution-free system. It features a fast deposition rate, high ionization rate, large ion energy, easy operation, low cost, and high production capacity.

The principle of vacuum arc ion coating is based on cold cathode, self-sustained arc discharge plasma evaporation. The material is ionized, and pulsed bias technology is applied to increase the energy and activity of deposited particles, thereby enhancing the coating properties. It can deposit coatings on both metal and non-metal surfaces.

| Mode | HCCA-2230 |

| Size | Ф2200×H3000mm |

| Structure | Vertical front door structure is equipped with air extraction system and water cooling system |

| Vacuum system | Mechanical pump+Roots pump+diffusion pump/Turbo molecular pump+holding pump |

| Vacuum measurement system | Pirani + cold cathode + film gauge |

| Coating system | Arc evaporation source,coating auxiliary ion dedicated power supply |

| Inflation system | Mass flowmeter |

| Power supply | DC power supply, intermediate frequency power supply, pulse power supply (bias power supply, arc power supply) |

| Control mode | Manual or automatic |

| Ultimate vacuum | 5.0x10-4Pa |

| Arc source | 22 set -28 set |

| 200A-300A | |

| Bias power supply | 60kW / set |

| Working rotation mode | Multi axis planetary public rotation, frequency control (controllable and adjustable) |

| Working baking temperature | Normal temperature to 450 ℃ controllable and adjustable (PID temperature control) |

| Process gas | Automatic filling system for 3 or 4-way process gas flow control and display system |

| Argon, nitrogen, oxygen, acetylene, etc | |

| Cooling mode | Water cooling cycle mode, with industrial cooling tower or industrial chiller (refrigerator) or cryogenic system. (provided by customer) |

| Control mode | PLC + touch screen operation or computer control, manual, semi-automatic, automatic mode |

| Supply index | Pressure 0.5-0.8MPa、Water temperature ≤25℃、Hydraulic pressure ≥0.2MPa |

| Alarm and protection | Alarm for water shortage, over-current, over-voltage, open circuit and other abnormal conditions of pump and target, and implement corresponding protection measures and electrical interlocking function |

| Total power | 185-200KW |

| Output frequency | The voltage is 380V ± 5%, and the frequency is 50 Hz (it can be configured according to the customer's national electricity standard) |

| Area | 35~55㎡ |

| Remarks | The above equipment parameters are only for reference, and are designed and customized according to the actual process requirements of customers |

| Mode | HCCA-2235 |

| Size | Ф2200×H3500mm |

| Structure | Vertical front door structure is equipped with air extraction system and water cooling system |

| Vacuum system | Mechanical pump+Roots pump+diffusion pump/Turbo molecular pump+holding pump |

| Vacuum measurement system | Pirani + cold cathode + film gauge |

| Coating system | Arc evaporation source,coating auxiliary ion dedicated power supply |

| Inflation system | Mass flowmeter |

| Power supply | DC power supply, intermediate frequency power supply, pulse power supply (bias power supply, arc power supply) |

| Control mode | Manual or automatic |

| Ultimate vacuum | 5.0x10-4Pa |

| Arc source | 22 set -28 set |

| 200A-300A | |

| Bias power supply | 60kW / set |

| Working rotation mode | Multi axis planetary public rotation, frequency control (controllable and adjustable) |

| Working baking temperature | Normal temperature to 450 ℃ controllable and adjustable (PID temperature control) |

| Process gas | Automatic filling system for 3 or 4-way process gas flow control and display system |

| Argon, nitrogen, oxygen, acetylene, etc | |

| Cooling mode | Water cooling cycle mode, with industrial cooling tower or industrial chiller (refrigerator) or cryogenic system. (provided by customer) |

| Control mode | PLC + touch screen operation or computer control, manual, semi-automatic, automatic mode |

| Supply index | Pressure 0.5-0.8MPa、Water temperature ≤25℃、Hydraulic pressure ≥0.2MPa |

| Alarm and protection | Alarm for water shortage, over-current, over-voltage, open circuit and other abnormal conditions of pump and target, and implement corresponding protection measures and electrical interlocking function |

| Total power | 185-200KW |

| Output frequency | The voltage is 380V ± 5%, and the frequency is 50 Hz (it can be configured according to the customer's national electricity standard) |

| Area | 35~55㎡ |

| Remarks | The above equipment parameters are only for reference, and are designed and customized according to the actual process requirements of customers |

| Mode | HCCA-2236 |

| Size | Ф2200×H3600mm |

| Structure | Vertical front door opening and hoisting structure are equipped with air extraction system and water cooling system |

| Vacuum system | Mechanical pump+Roots pump+diffusion pump/Turbo molecular pump+holding pump |

| Vacuum measurement system | Pirani + cold cathode + film gauge |

| Coating system | Arc evaporation source,coating auxiliary ion dedicated power supply |

| Inflation system | Mass flowmeter |

| Power supply | DC power supply, intermediate frequency power supply, pulse power supply (bias power supply, arc power supply) |

| Control mode | Manual or automatic |

| Ultimate vacuum | 5.0x10-4Pa |

| Arc source | 22 set -28 set |

| 200A-300A | |

| Bias power supply | 60kW / set |

| Working rotation mode | Multi axis planetary public rotation, frequency control (controllable and adjustable) |

| Working baking temperature | Normal temperature to 450 ℃ controllable and adjustable (PID temperature control) |

| Process gas | Automatic filling system for 3 or 4-way process gas flow control and display system |

| Argon, nitrogen, oxygen, acetylene, etc | |

| Cooling mode | Water cooling cycle mode, with industrial cooling tower or industrial chiller (refrigerator) or cryogenic system. (provided by customer) |

| Control mode | PLC + touch screen operation or computer control, manual, semi-automatic, automatic mode |

| Supply index | Pressure 0.5-0.8MPa、Water temperature ≤25℃、Hydraulic pressure ≥0.2MPa |

| Alarm and protection | Alarm for water shortage, over-current, over-voltage, open circuit and other abnormal conditions of pump and target, and implement corresponding protection measures and electrical interlocking function |

| Total power | 185-200KW |

| Output frequency | The voltage is 380V ± 5%, and the frequency is 50 Hz (it can be configured according to the customer's national electricity standard) |

| Area | 35~55㎡ |

| Remarks | The above equipment parameters are only for reference, and are designed and customized according to the actual process requirements of customers |

| Mode | HCCA-2240 |

| Size | Ф2200×H4000mm |

| Structure | Vertical front door opening and hoisting structure are equipped with air extraction system and water cooling system |

| Vacuum system | Mechanical pump+Roots pump+diffusion pump/Turbo molecular pump+holding pump |

| Vacuum measurement system | Pirani + cold cathode + film gauge |

| Coating system | Arc evaporation source,coating auxiliary ion dedicated power supply |

| Inflation system | Mass flowmeter |

| Power supply | DC power supply, intermediate frequency power supply, pulse power supply (bias power supply, arc power supply) |

| Control mode | Manual or automatic |

| Ultimate vacuum | 5.0x10-4Pa |

| Arc source | 22 set -28 set |

| 200A-300A | |

| Bias power supply | 60kW / set |

| Working rotation mode | Multi axis planetary public rotation, frequency control (controllable and adjustable) |

| Working baking temperature | Normal temperature to 450 ℃ controllable and adjustable (PID temperature control) |

| Process gas | Automatic filling system for 3 or 4-way process gas flow control and display system |

| Argon, nitrogen, oxygen, acetylene, etc | |

| Cooling mode | Water cooling cycle mode, with industrial cooling tower or industrial chiller (refrigerator) or cryogenic system. (provided by customer) |

| Control mode | PLC + touch screen operation or computer control, manual, semi-automatic, automatic mode |

| Supply index | Pressure 0.5-0.8MPa、Water temperature ≤25℃、Hydraulic pressure ≥0.2MPa |

| Alarm and protection | Alarm for water shortage, over-current, over-voltage, open circuit and other abnormal conditions of pump and target, and implement corresponding protection measures and electrical interlocking function |

| Total power | 185-200KW |

| Output frequency | The voltage is 380V ± 5%, and the frequency is 50 Hz (it can be configured according to the customer's national electricity standard) |

| Area | 35~55㎡ |

| Remarks | The above equipment parameters are only for reference, and are designed and customized according to the actual process requirements of customers |

| Mode | HCCA-2245 |

| Size | Ф2200×H4500mm |

| Structure | Vertical front door structure is equipped with air extraction system and water cooling system |

| Vacuum system | Mechanical pump+Roots pump+diffusion pump/Turbo molecular pump+holding pump |

| Vacuum measurement system | Pirani + cold cathode + film gauge |

| Coating system | Arc evaporation source,coating auxiliary ion dedicated power supply |

| Inflation system | Mass flowmeter |

| Power supply | DC power supply, intermediate frequency power supply, pulse power supply (bias power supply, arc power supply) |

| Control mode | Manual or automatic |

| Ultimate vacuum | 5.0x10-4Pa |

| Arc source | 22 set -28 set |

| 200A-300A | |

| Bias power supply | 60kW / set |

| Working rotation mode | Multi axis planetary public rotation, frequency control (controllable and adjustable) |

| Working baking temperature | Normal temperature to 450 ℃ controllable and adjustable (PID temperature control) |

| Process gas | Automatic filling system for 3 or 4-way process gas flow control and display system |

| Argon, nitrogen, oxygen, acetylene, etc | |

| Cooling mode | Water cooling cycle mode, with industrial cooling tower or industrial chiller (refrigerator) or cryogenic system. (provided by customer) |

| Control mode | PLC + touch screen operation or computer control, manual, semi-automatic, automatic mode |

| Supply index | Pressure 0.5-0.8MPa、Water temperature ≤25℃、Hydraulic pressure ≥0.2MPa |

| Alarm and protection | Alarm for water shortage, over-current, over-voltage, open circuit and other abnormal conditions of pump and target, and implement corresponding protection measures and electrical interlocking function |

| Total power | 185-200KW |

| Output frequency | The voltage is 380V ± 5%, and the frequency is 50 Hz (it can be configured according to the customer's national electricity standard) |

| Area | 35~55㎡ |

| Remarks | The above equipment parameters are only for reference, and are designed and customized according to the actual process requirements of customers |

| Mode | HCCA-2345 |

| Size | Ф2300×H4500mm |

| Structure | Vertical front door opening and hoisting structure are equipped with air extraction system and water cooling system |

| Vacuum system | Mechanical pump+Roots pump+diffusion pump/Turbo molecular pump+holding pump |

| Vacuum measurement system | Pirani + cold cathode + film gauge |

| Coating system | Arc evaporation source,coating auxiliary ion dedicated power supply |

| Inflation system | Mass flowmeter |

| Power supply | DC power supply, intermediate frequency power supply, pulse power supply (bias power supply, arc power supply) |

| Control mode | Manual or automatic |

| Ultimate vacuum | 5.0x10-4Pa |

| Arc source | 22 set -28 set |

| 200A-300A | |

| Bias power supply | 60kW / set |

| Working rotation mode | Multi axis planetary public rotation, frequency control (controllable and adjustable) |

| Working baking temperature | Normal temperature to 450 ℃ controllable and adjustable (PID temperature control) |

| Process gas | Automatic filling system for 3 or 4-way process gas flow control and display system |

| Argon, nitrogen, oxygen, acetylene, etc | |

| Cooling mode | Water cooling cycle mode, with industrial cooling tower or industrial chiller (refrigerator) or cryogenic system. (provided by customer) |

| Control mode | PLC + touch screen operation or computer control, manual, semi-automatic, automatic mode |

| Supply index | Pressure 0.5-0.8MPa、Water temperature ≤25℃、Hydraulic pressure ≥0.2MPa |

| Alarm and protection | Alarm for water shortage, over-current, over-voltage, open circuit and other abnormal conditions of pump and target, and implement corresponding protection measures and electrical interlocking function |

| Total power | 185-200KW |

| Output frequency | The voltage is 380V ± 5%, and the frequency is 50 Hz (it can be configured according to the customer's national electricity standard) |

| Area | 35~55㎡ |

| Remarks | The above equipment parameters are only for reference, and are designed and customized according to the actual process requirements of customers |

| Mode | HCCA-2545 |

| Size | Ф2500×H4500mm |

| Structure | Vertical front door opening and hoisting structure are equipped with air extraction system and water cooling system |

| Vacuum system | Mechanical pump+Roots pump+diffusion pump/Turbo molecular pump+holding pump |

| Vacuum measurement system | Pirani + cold cathode + film gauge |

| Coating system | Arc evaporation source,coating auxiliary ion dedicated power supply |

| Inflation system | Mass flowmeter |

| Power supply | DC power supply, intermediate frequency power supply, pulse power supply (bias power supply, arc power supply) |

| Control mode | Manual or automatic |

| Ultimate vacuum | 5.0x10-4Pa |

| Arc source | 22 set -28 set |

| 200A-300A | |

| Bias power supply | 60kW / set |

| Working rotation mode | Multi axis planetary public rotation, frequency control (controllable and adjustable) |

| Working baking temperature | Normal temperature to 450 ℃ controllable and adjustable (PID temperature control) |

| Process gas | Automatic filling system for 3 or 4-way process gas flow control and display system |

| Argon, nitrogen, oxygen, acetylene, etc | |

| Cooling mode | Water cooling cycle mode, with industrial cooling tower or industrial chiller (refrigerator) or cryogenic system. (provided by customer) |

| Control mode | PLC + touch screen operation or computer control, manual, semi-automatic, automatic mode |

| Supply index | Pressure 0.5-0.8MPa、Water temperature ≤25℃、Hydraulic pressure ≥0.2MPa |

| Alarm and protection | Alarm for water shortage, over-current, over-voltage, open circuit and other abnormal conditions of pump and target, and implement corresponding protection measures and electrical interlocking function |

| Total power | 185-200KW |

| Output frequency | The voltage is 380V ± 5%, and the frequency is 50 Hz (it can be configured according to the customer's national electricity standard) |

| Area | 35~55㎡ |

| Remarks | The above equipment parameters are only for reference, and are designed and customized according to the actual process requirements of customers |

Looking for a solution tailored to your needs? Our team is ready to provide you with expert guidance and support.