PVD (Physical Vapor Deposition) is a vacuum-based coating technology that turns solid materials—like metals—into vapor and deposits them onto surfaces as thin, durable films. During the process, materials can react with gases such as nitrogen to form hard, functional coatings like nitrides. PVD coatings are clean, eco-friendly, and widely used to improve surface properties like wear resistance, corrosion protection, and decorative appearance.

Details

Atomic layer deposition (ALD) is a technique used to deposit thin films one atomic layer at a time. This technology is highly precise and offers excellent control over the film thickness.

Details

Chemical vapor deposition (CVD) is a process used to produce thin films through chemical reactions that occur when gas-phase precursors react on the substrate surface.

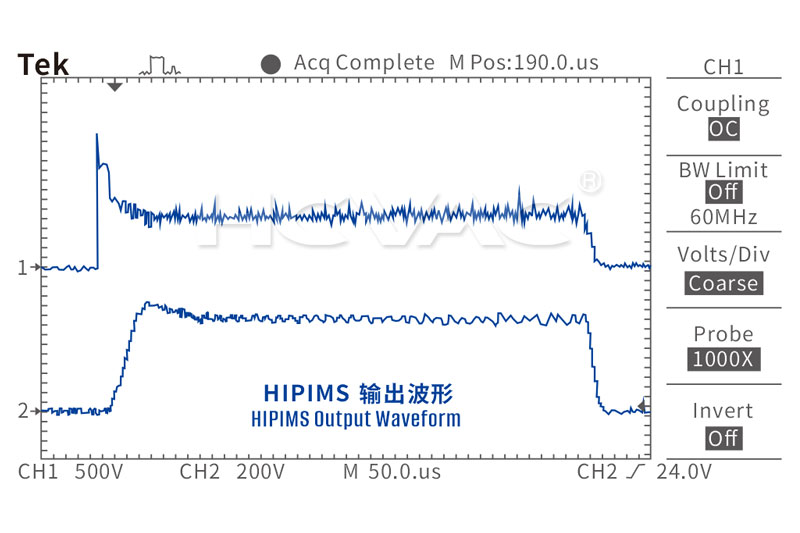

DetailsHIPIMS

Applies high-power pulsed plasma to achieve high ionization and dense, uniform coatings.

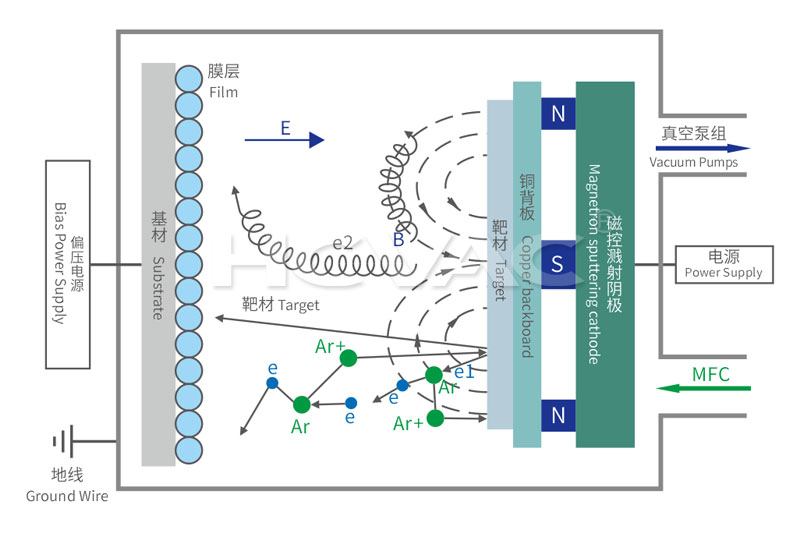

Magnetron Sputtering

Uses a magnetic field to enhance plasma and sputter target atoms onto the substrate.

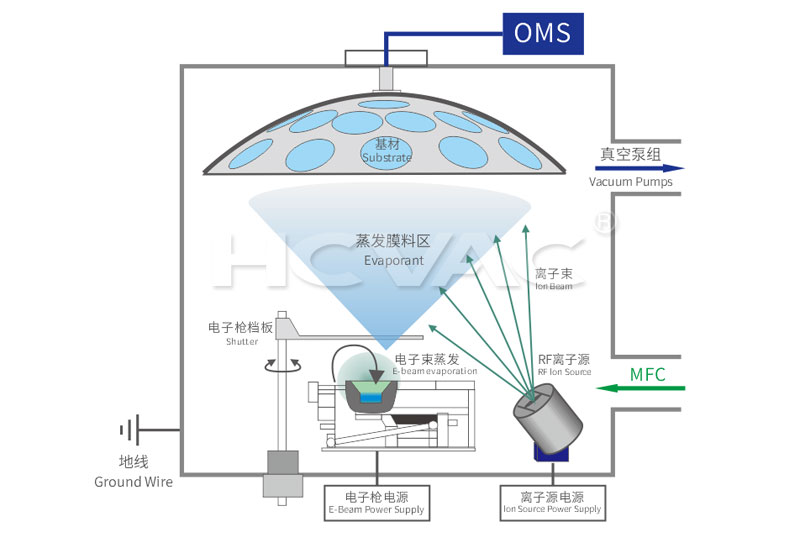

E-beam Evaporation

Uses a high-energy electron beam to heat and evaporate materials for film deposition.

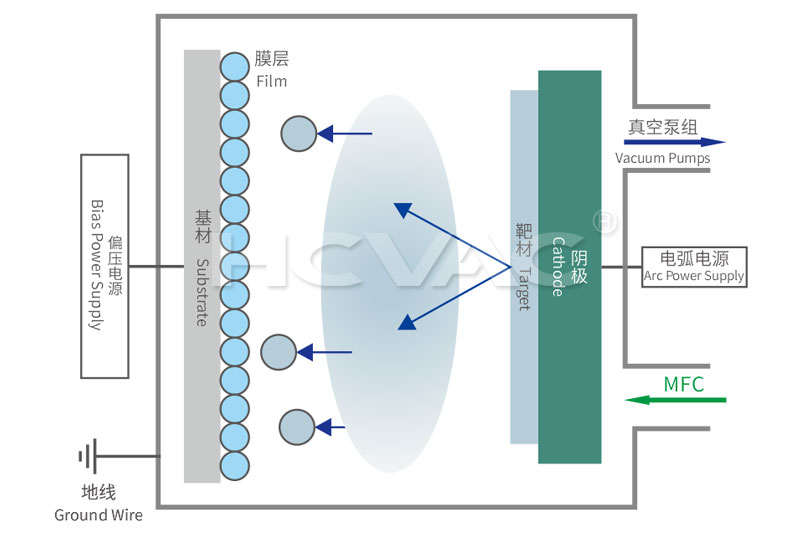

Arc Ion Plating

Uses a vacuum arc to vaporize the target material, depositing it as ions on the substrate.

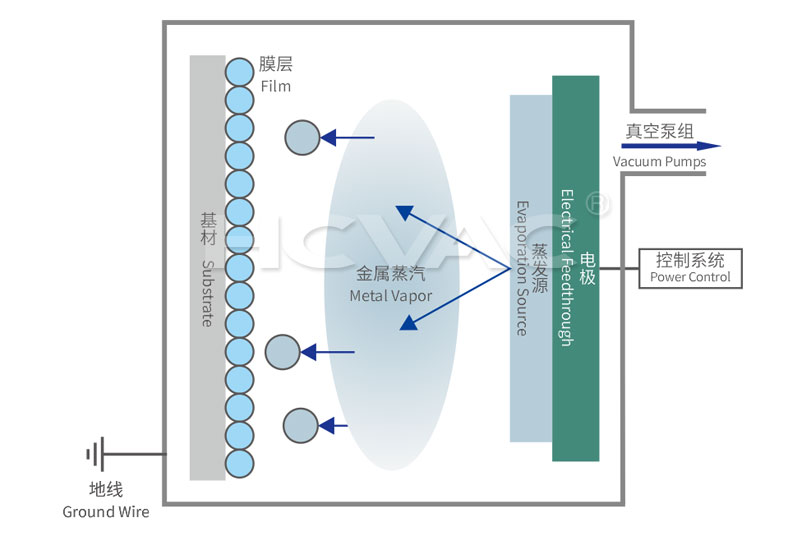

Thermal Evaporation

Heats materials by resistive heating until they evaporate and form a thin film.

Atomic layer deposition (ALD) is a method that can deposit materials on the substrate surface layer by layer in the form of single atomic film, so as to form a full coverage film on the substrate surface with complex morphology.

TALD

It stands for Thermal Atomic Layer Deposition. Uses thermal energy to sequentially deposit thin atomic layers on a substrate for precise film control.

PEALD

It stands for Plasma-Enhanced Atomic Layer Deposition. Uses plasma to enhance chemical reactions during the atomic layer deposition process, enabling lower temperatures and wider material compatibility.

CVD stands for Chemical Vapor Deposition,. it is a technique that deposits high-purity, uniform thin films by introducing reactive gases into a chamber, where they chemically react or decompose on the heated substrate surface to form a solid coating.

Subscribe to our newsletter and stay updated with latest vacuum coating tech!