Atomic layer deposition (ALD) is a method that can deposit materials on the substrate surface layer by layer in the form of single atomic film, so as to form a full coverage film on the substrate surface with complex morphology.

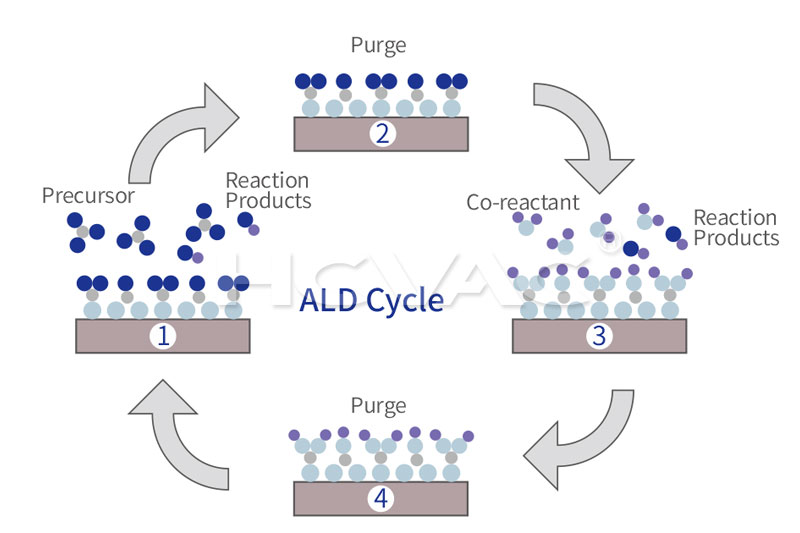

Atomic layer deposition is similar to ordinary chemical deposition, but in the process of atomic layer deposition, the chemical reaction of a new atomic film is directly related to the previous layer, so only one layer of atoms is deposited in each reaction.

In the ALD process, different reaction precursors are alternately sent into the reaction chamber in the form of gas pulses. Therefore, it has the characteristics of self limiting growth, and the thickness of the film can be accurately controlled. The prepared film has uniform thickness, excellent consistency and high step coverage, which is especially suitable for the film growth in deep groove structure, It has irreplaceable applications for the demand of accurate film-forming on the surface of multi-dimensional structures.

Since ALD equipment can realize high aspect ratio, excellent step coverage of extremely narrow groove opening and accurate film thickness control, ALD is one of the essential core equipment in the manufacturing of advanced logic chips, DRAM and 3D NAND with complex structure and accurate film thickness requirements.