We are the leading PVD machine manufacturer for the widest applications. Our PVD systems enhance surfaces with rich colors and advanced features, like precise optical films, super hard films, and more. Keep exploring and discover how our solutions can transform your product.

Decorative pvd coating machine can deposit decorative effect coating on the surface of hardware, stainless steel plate, stainless steel tube, glass, ceramics, plastic, acrylic, resin, etc. it has the advantages of simple operation, low cost and large production. It is widely used in jewelry, clock, lighting, kitchen and sanitary ware, construction, medical treatment, catering, scientific research, digital, entertainment, electrical appliances, cosmetics, toys and other industries, and the production after coating Products can show a variety of beautiful effects, such as elegant, dazzling, and the film will not fade for a long time.

Various kinds of films with optical generation can be prepared to change the transmittance and reflectivity characteristics of the substrate materials they are applied to, such as AR, UV / IR cut-off filter, AF, metal film for motor, hard ar film, enhanced reflection film, hard film, decorative film, ITO film, dichroic mirror, band-pass filter, polarizing tree Grease, RGB filter, photocatalyst, HR film, etc. are widely used in digital cameras, smartphones, glasses, projectors, optical pickups, optical communications, LEDs, electronic products, decorative products, solar cells, displays, etc.

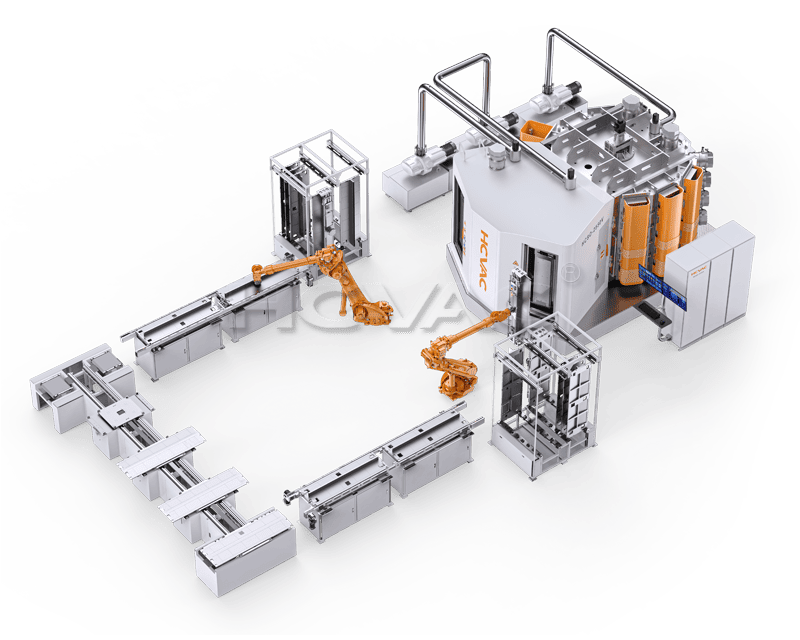

Functional pvd coating machine Based on PMA-I patent technology, HCVAC developed PMA-II patent technology and successfully integrated PMA-II technology into the new generation HCSH coating system. The system has flexible configuration and can be combined with arc, MS, hipims and other technologies to provide more possibilities for the development of new coatings and materials, and is widely used in scientific research, semiconductors, tools, tools, molds, parts, medical devices, optics, new energy and other industries.

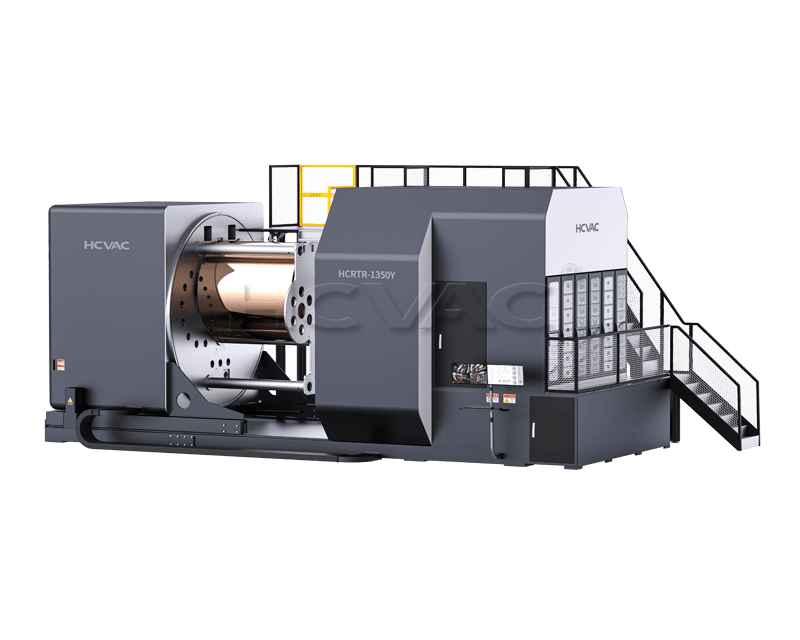

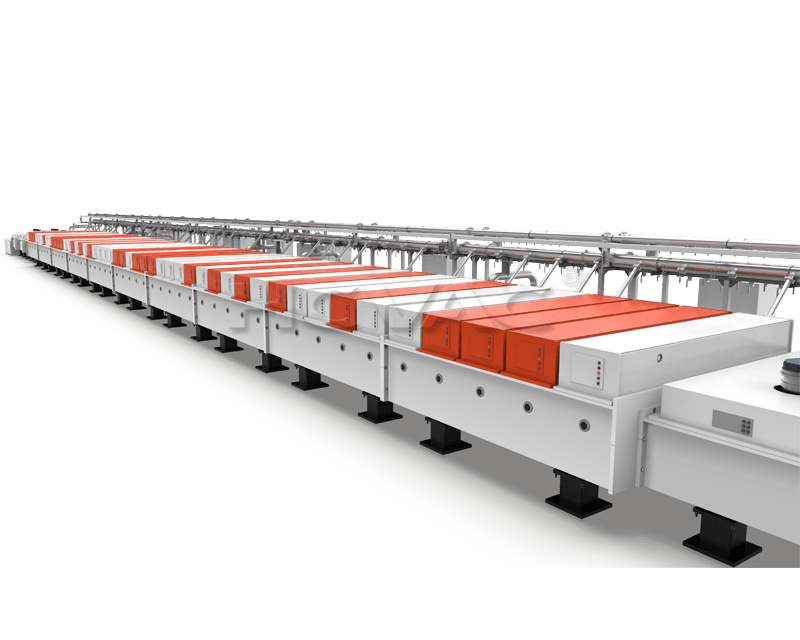

PVD technology of magnetron sputtering or evaporation is used for continuous coating on strip substrate. Magnetron sputtering can be used for continuous coating on strip coil surface such as pet, PI, PC, cop, other flexible polymers and metal strips. It can be used for aluminum, titanium, chromium, copper, nichrome, nickel, silver and other metal materials, TiO2, Nb2O5, SiO2, ITO, sialox, MoOx and other nitrides or oxides. Evaporation can be used for continuous coating on pet, (b) OPP, PVC, CPP and other macromolecular films, paper, metal foil, aluminum, copper, silver and other metal materials, ZnS, SiO, MGF and other compounds.

HCVAC provides vacuum coating machine or pvd coating machine and process applied to auto lamp or interior lighting industry parts, interior trim, etc., such as auto headlight and tail lamp, auto rearview mirror, car logo, car grid, door handle, door and window light strip, interior trim strip, interior lighting, etc. This series of equipment is equipped with plasma treatment device, high-efficiency magnetron sputtering cathode and resistance evaporation device, etc. the deposition rate of the equipment is fast, the coating adhesion is good, the coating is fine and dense, the surface finish is high, and the uniformity is good.

It is mainly used for plating high-quality, high-performance metal film, electromagnetic shielding film, reaction film, composite film, transparent conductive film, antireflection (AR), antireflection film, Low-E film on flat glass, acrylic, PC, pet and other surfaces. The company can provide design, complete equipment, process and "key" engineering services according to user requirements.

Enioy durable surfaces, eye-catching finishes, and improved performance that make your products stand out, Get personalized advice, detailed information, and answers to all your questions. Our team is here to help!

Real Results from PVD Equipment

We're pleased to solve your challenges and help you achieve your goals with our expertise