Our ALD (Atomic Layer Deposition) equipment plays a crucial role in semiconductors, optics, MEMS, and photovoltaics, delivering ultra-uniform, high-conformality thin films with atomic-level thickness control.

It ensures precise and defect-free coatings even on complex 3D structures, deep trenches, and high-aspect-ratio components, making it an ideal solution for next-generation technology.

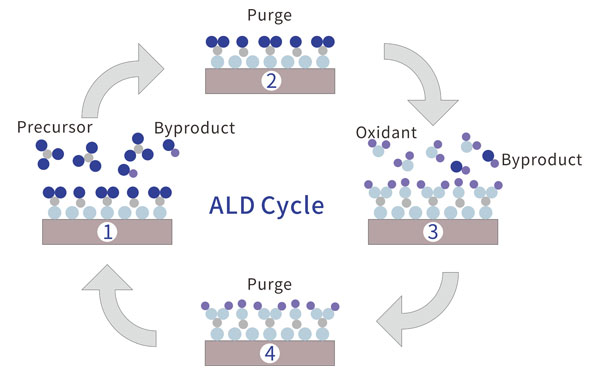

ALD is a type of CVD technology. It alternately introduces different chemical vapor precursors, conducts self-limiting chemical reactions on the substrate surface, and finally deposits thin films layer by layer, ensuring precise thickness control.

TALD uses thermal sources to heat precursor gases for atomic layer deposition, is suitable for high-temperature deposition. PEALD, on the other hand, uses plasma to excite precursor gases, allowing deposition at lower temperatures, more suitable for temperature-sensitive materials.

We offer tailored atomic layer deposition solutions and equipment configurations based on your specific needs

We provide high-quality, stable, and reliable equipment, offering full support throughout the entire lifecycle, covering all aspects from design and installation to maintenance

If you are in the semiconductor, optics, MEMS, or photovoltaics field and need to deposit films on complex structures, ALD is your ideal solution. Our equipment offers precise control over film thickness, excellent uniformity, and conformal coating on high aspect ratio structures. Contact us today to explore how our ALD technology can meet your needs!

Coated / No coating

We're pleased to solve your challenges and help you achieve your goals with our expertise