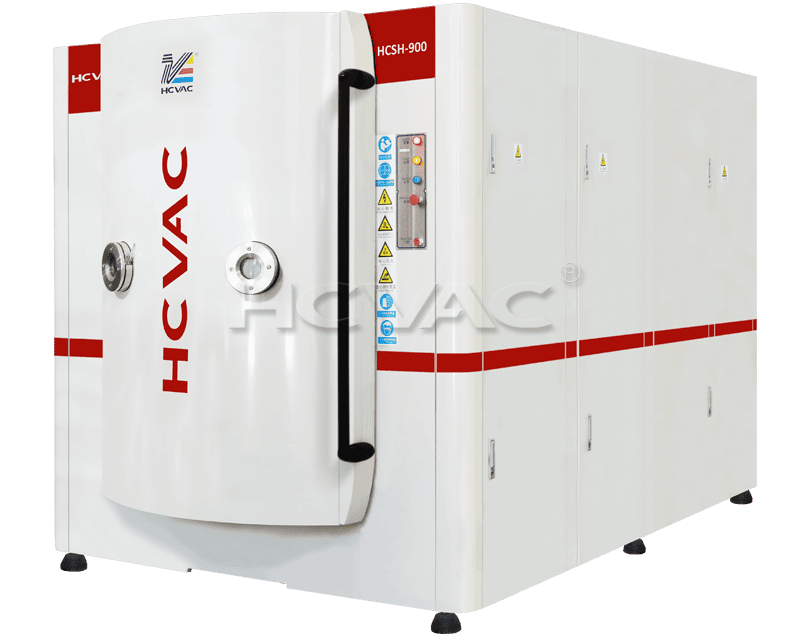

Hipims-800 is capable of depositing all available HCVAC sputtered coatings and almost all PVD coatings on the market.

In addition, it is an ideal machine for developing custom processes. The customer-friendly user interface "data view" and the integrated planning tool "data plan" help design separate coating solutions. Your coating will make your products stand out in the market and give users a competitive advantage.

Other features, such as user-friendly tablet and mobile phone remote control, easy to maintain components, fully automatic cathode blinds, automatic door closing and quick change of coating table, make hipims-800 the best coating system for the production and development of state-of-the-art high-performance coatings.

Key Features of HiPIMS High Power Impulse Magnetron Sputtering Coating Machine

The deposition rate is as high as 2 µm / h

Uniform deposition rate in the whole chamber

The process cycle of pure HiPIMS AlTiN is 4 hours and 30 minutes

Minimum conversion time, covering new coating materials and other tool

Fully automatic, low maintenance requirements

Local or remote monitoring of coating process

The hipims-800 combines all the advantages of a classic DC sputtering coating system with the capabilities of the latest hipims technology.

The system is equipped with six sputtering cathodes, four of which can work in hipims or DC mode. The other two DC cathodes can be operated, for example, to provide more complex multilayer coatings, provide color and top coating, or simply increase the deposition rate.

The absolute combination of these technologies in one process provides a limited range of coating designs at very low production costs.

In the pure hipims mode, the deposition rate is 2 μ M / h, and the treatment time is 4-5 hours. When all six cathodes work at the same time, it can reach 3 μ M / h. This is so far an incredible low production time for 1.800 round shank tools or 5.000 indexable inserts coating capacity.

The innovative APA evaporator technology (Advanced Plasma Assisted) is based on cathodic vacuum arc and offers diverse development possibilities for new layer architectures.

Benefits:

●High target utilisation result in low target costs

●High deposition rates

●Adjustable magnetic fields

●Short target changing times

●High plasma density

●Reduction of macro-particles

●Excellent coating adhesion

HiPIMS stands for High-Power Impulse Magnetron Sputtering.

Benefits:

●High ionisation rate (similar to arc)

●High power densities from 100 to 1000 W/cm2

●Very high plasma density

●Layer structures adjustable by plasma parameter settings

●Very smooth coatings

●Excellent coating adhesion

●Deposition of dense coatings at low substrate temperatures

In the sputtering process, atoms are extracted from a target by bombardment with high-energy ions (Ar) and transformed into the gas phase. By combining the sputtered material with additional gases, a coating is deposited on the substrate.

Benefits:

● A wide range of materials can be sputtered

● Diverse process variants available

● Smooth coatings

● Good coating adhesion on combination with power etching prozess AEGD

With the nitriding module, a plasma nitriding process can be performed before a PVD and/or PACVD coating process in one system and one batch. Thereby a hardened layer can be produced which offers excellent support for the subsequent PVD/PACVD coating.

Benefits:

● Optimisation of tool and component properties

● Substitution of expensive base materials

● Significantly longer lifetimes

● All PVD coatings can be applied

DLC stands for Diamond-Like Carbon and refers to a group of extremely low friction amorphous carbon coatings. With the DLC module, different DLC coatings can be produced by using PVD and/or PACVD processes. Standard DLC coatings consist of metal free or metal containing carbon coatings.

Benefits:

● Excellent coating adhesion

● High wear resistance

● Low coefficient of friction

● Smooth coatings

ta-C stands for tetrahedral amorphous carbon without hydrogen and refers to a group of extremely hard and low friction amorphous carbon coatings. With the ta-C module different ta-C coatings can be produced.

Benefits:

● For higher temperature environments than DLC

● Very high wear resistance

● Excellent coating adhesion

● Smooth coatings

| Mode | HiPIMS-800 |

| Coating area | Ø400mm x 400mm |

| Substrate table | Ø400mm xØ130mm x 6 |

| Table for quick batch change | Optional |

| Sputter cathodes | 6 x 500 (including 4 optional HiPIMS/DC and another 2 DC; all cathodes equipped with shutters) |

| Maximum substrate dimensions Ø x h | Ø400mm x 800mm |

| Drill capacity Ø6 mm x 60 mm | 1800 |

| Insert capacity 12.7 mm x 3.5 mm | 4920 |

| Maximum subtrate weight | 250KG |

| Deposition rate | In pure HiPIMS mode 2μm/h In DC or combi mode up to 3 μm/h。” |

| Cycle time* | 4.5H |

| Processes | HiPIMS and Sputtering using booster technology. All established HCVAC coatings are possible. |

| Substrate pre-treatment (plasma etching) | Booster, MF and HiPIMS, etching |

| Electrically conductive coatings | Yes |

| Electrically non-conductive coatings | Yes |

| Electrically non-conductive substrates | Yes |

| Rated power | 80Kw |

| Power consumption per batch for 3 µm coating | 120kWh |

| Outer dimensions | 1450mm x 3350mm x 2200mm |

| Weight (empty) | ~3500Kg |

| Closing of chamber doors | Automatic closing |

| * Pure HiPIMS coating on 10 mm milling cutter | |

Looking for a solution tailored to your needs? Our team is ready to provide you with expert guidance and support.