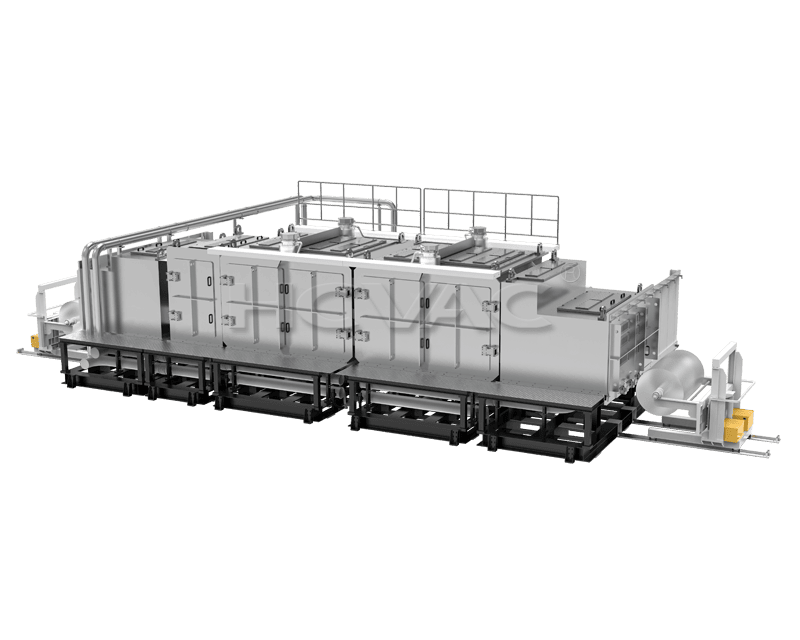

The HCFLC series flexible electronic coating machine offers a competitive, cost-effective solution for coating flexible and wearable electronics, sensors, RFID tags, smart glass, smart packaging, and more. It enables the application of high-quality, low-resistivity copper or TCO layers—bridging the gap between productivity and versatility to meet current and future market needs.

Ideal for ITO film, FPCB, Low-E, and smart glass applications, the system features a rotatable magnetron with up to 2000 mm coating width and supports substrate rollers up to 500 mm in diameter. Optional gas separation between process sections allows multiple metal and dielectric layers to be deposited in one run.

Key Features of Flexible Electronic Roll to Roll Vacuum Coating Machine

High system versatility and flexibility

Intelligent machine concept guarantees quality

Easy to operate and clean

Minimum floor area of facilities

Temperature controlled coated roller (- 15 to + 80 ° C)

Easy maintenance and high machine uptime

The HCFLC series is an ideal solution for both production and R&D. With nearly unlimited configurations—supporting up to six sets of rotatable magnetrons—it offers high flexibility. A wide range of in-situ sensors allows real-time monitoring, making it suitable for stable production while remaining adaptable for research and development.

The system supports simultaneous reactive and non-reactive sputtering processes and can be equipped with sensors to continuously and accurately monitor key film properties such as resistivity, reflectivity, and transmittance.

| Model | HCFLC-400 |

| Wide in width | 400mm |

| Diameter(mm) | Max.500 |

| Winding speed | 0.1–25.0 m/min |

| Winding tension | 25–600 N |

| Base material | Based on pet, pen, PI, Al, SST, copper, flexible glass, etc |

| Coating | AG, Al, Cu, Cr, Ni, Ti |

| Dielectric | AZO, ITO, SiO2, SiN, SnO2, Nb2O5, TiO2 |

| Model | HCFLC-650 |

| Wide in width | 650mm |

| Diameter(mm) | Max.500 |

| Winding speed | 0.1–25.0 m/min |

| Winding tension | 25–600 N |

| Base material | Based on pet, pen, PI, Al, SST, copper, flexible glass, etc |

| Coating | AG, Al, Cu, Cr, Ni, Ti |

| Dielectric | AZO, ITO, SiO2, SiN, SnO2, Nb2O5, TiO2 |

| Model | HCFLC-1650 |

| Wide in width | 1650mm |

| Diameter(mm) | Max.500 |

| Winding speed | 0.1–25.0 m/min |

| Winding tension | 25–600 N |

| Base material | Based on pet, pen, PI, Al, SST, copper, flexible glass, etc |

| Coating | AG, Al, Cu, Cr, Ni, Ti |

| Dielectric | AZO, ITO, SiO2, SiN, SnO2, Nb2O5, TiO2 |

| Model | HCFLC-2000 |

| Wide in width | 2000mm |

| Diameter(mm) | Max.500 |

| Winding speed | 0.1–25.0 m/min |

| Winding tension | 25–600 N |

| Base material | Based on pet, pen, PI, Al, SST, copper, flexible glass, etc |

| Coating | AG, Al, Cu, Cr, Ni, Ti |

| Dielectric | AZO, ITO, SiO2, SiN, SnO2, Nb2O5, TiO2 |

Looking for a solution tailored to your needs? Our team is ready to provide you with expert guidance and support.