This machine is suitable for coating ultra-hard AR+ DLC+ AF multi-layer composite films. The coatings not only offer excellent optical properties but also perform outstandingly in hardness, corrosion resistance, and surface wear resistance.

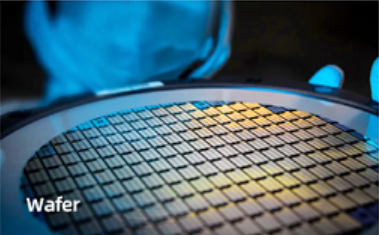

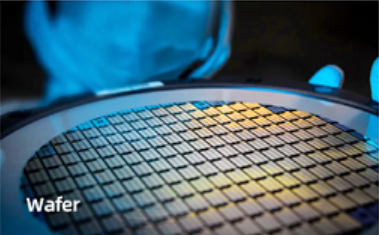

It is widely used in in-car display, laptop glass panels, AR film deposition on 3C product glass front covers, color films (including gradient color films) for 3C product back covers, and NCVM film processing.

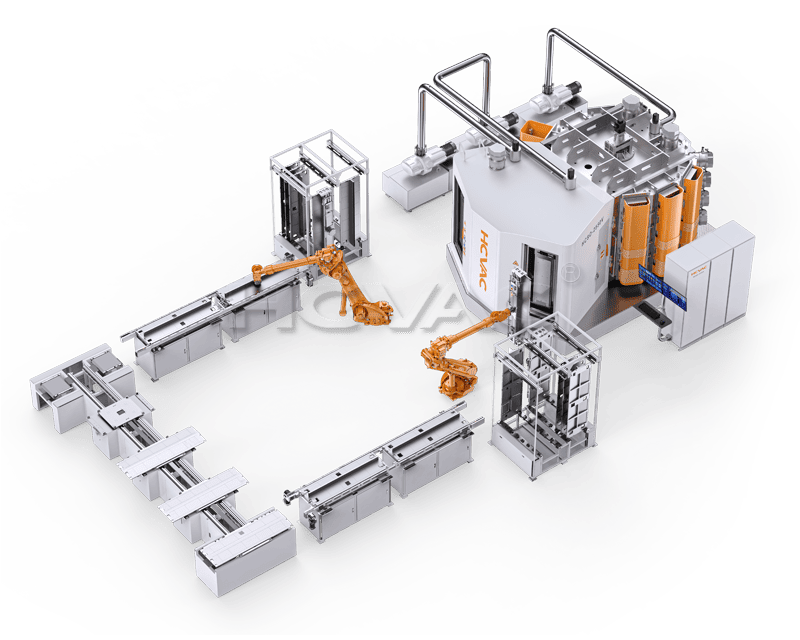

Key Features of Multi Cavity Magnetron Sputtering DLC+AR+AF/AS Optical Coating Machine

AR, DLC, AF layers in one deposition

Ultra-hard coatings (Mohs 7), wear and scratch resistant

Simultaneous loading and unloading, vacuum/evacuation, wafer transfer, short waiting time

Achieves nanometer-level precision in film thickness

Uniform and reliable coatings with uniformity within ±1%.

Achieves high-quality coatings at lower temperatures, ideal for temperature-sensitive materials

The equipment uses RF ion source cleaning and post-oxidation assisted sputtering to deposit uniform, dense, high-hardness films. The automatic robotic system transfers substrates between the load and unload chambers, and precise vacuum control ensures consistent deposition with uniformity under ±1% in mass production. Simultaneous loading, unloading, vacuum pumping/breaking, and substrate transfer significantly improve production efficiency.

By optimizing the sputtering source and process parameters, the film achieves a Mohs hardness of 7 at 750g load, greatly enhancing scratch resistance and durability. The AR layer offers high transparency and low reflectivity, improving optical performance; the DLC layer provides high hardness and wear resistance; the AF layer reduces surface energy, offering fingerprint resistance and easy cleaning, with steel wool abrasion resistance of 10,000 cycles at ≥100°.

| Dimensions | Ф2700mm*H2350mm |

| Structure | Three-chamber structure (Loading chamber + Process chamber + Unloading chamber) |

| Performance | |

| Rotation Speed | 10~100RPM(Variable) |

| Loading/Unloading Chamber Pumping Speed | Atmospheric pressure to 10Pa ≤5min |

| Process Chamber Pumping Speed | 3.0×10-3Pa≤15min |

| Ultimate Vacuum | 8.0×10-5Pa (Film deposition chamber) |

| Sputtering Target Materials | Nb,Si,Cr,Al,Ti,In,Nb2O5, ITO,C ... |

| Main Components | |

| Fixture System | Central rotating and translating fixture barrel / Hanging plate mechanical structure drive |

| Hanging Plate | Φ2550x H1200 ~ H1800mm Hanging Plate Size Customizable |

| Exhaust System | Low vacuum pump set + High vacuum pump set + Polycold |

| Vacuum Control System | Vacuum controller, Penning and Pirani vacuum gauges |

| Coating System | MF magnetron sputtering source + Plasma source + Online AF/AS evaporation source |

| Gas Control System | MFC or APC automatic pressure controller |

| Control System | PC+PLC |

| Applications | |

| Optical Coating Applications | UV cut-off filters, AR, hard AR coatings, hard coatings, HR coatings, AS/AF, etc., compatible with 2D/3D substrates |

| Applicable Wavelength | 300nm~780nm |

| Note: Customizable (Data for reference only) | |

| Dimensions | Ф2700mm*H1950mm |

| Structure | Two-chamber structure (Loading chamber + Process chamber + Unloading chamber) |

| Performance | |

| Rotation Speed | 10~100RPM(Variable) |

| Loading/Unloading Chamber Pumping Speed | Atmospheric pressure to 10Pa ≤5min |

| Process Chamber Pumping Speed | 3.0×10-3Pa≤15min |

| Ultimate Vacuum | 8.0×10-5Pa (Film deposition chamber) |

| Sputtering Target Materials | Nb,Si,Cr,Al,Ti,In,Nb2O5, ITO,C ... |

| Main Components | |

| Fixture System | Central rotating and translating fixture barrel / Hanging plate mechanical structure drive |

| Hanging Plate | Φ2550x H1200 ~ H1800mm Hanging Plate Size Customizable |

| Exhaust System | Low vacuum pump set + High vacuum pump set + Polycold |

| Vacuum Control System | Vacuum controller, Penning and Pirani vacuum gauges |

| Coating System | MF magnetron sputtering source + Plasma source + Online AF/AS evaporation source |

| Gas Control System | MFC or APC automatic pressure controller |

| Control System | PC+PLC |

| Applications | |

| Optical Coating Applications | UV cut-off filters, AR, hard AR coatings, hard coatings, HR coatings, AS/AF, etc., compatible with 2D/3D substrates |

| Applicable Wavelength | 300nm~780nm |

| Note: Customizable (Data for reference only) | |

Looking for a solution tailored to your needs? Our team is ready to provide you with expert guidance and support.