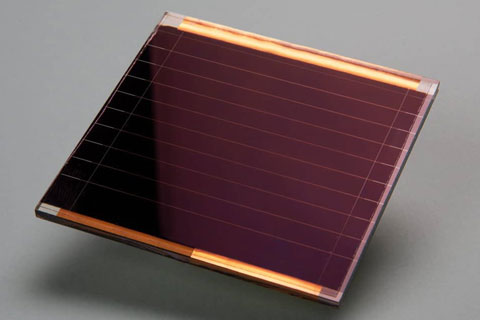

It is suitable for forming high-precision optical multilayer films on glass, PC, or PMMA substrates. The films includes:

AR film (substrate glass transmittance > 91.5%):

Color film or gradient film:

Key Features of High Precision E-beam Evaporation Optical Coating Machine

Precision system of high precision optical multilayer film

Multiple component combinations to meet customer needs

Easy to operate and maintain

High performance, high throughput

Automatic evaporation control system to realize automatic evaporation process

Provide factory remote diagnostics

The multi-layer film can be stably formed using the electron beam heating method, with the crucible acting as the evaporation source without an electrode. The high-precision, stable optical multi-layer film is produced using the company's unique ratio control method and multi-point online monitoring. The base umbrella frame is easily removed with an elevator, ensuring good operability. The umbrella frame of the substrate adopts a central rotation mode to reduce vibration and particle contamination, enabling stable substrate rotation.

The ion source, with uniform distribution and high ion current density, is equipped with double electron guns. The multi-point and ring crucibles can deposit more than 100 layers. The automatic evaporation process is controlled by the automatic evaporation control system, and the workpiece frame can be either bell-type or planetary-type.

| Mode | HCEB-900 |

| Size(mm) | Φ900 x H1300 |

| Structure | Vertical Chamber with single Door, SUS304 Stainless Steel |

| Wavelength | 300nm~1100nm |

| Rotational speed | 0~60RPM (variable) |

| Pumping speed | Atmospheric pressure to 1.5×10-3Pa less than 30min |

| Ultimate vacuum | 8.0×10-5Pa |

| Coating material | Tio2, Ti3o5, H4, Zro2, Zns, Al2o3, Mgf2, Sio2, Au, Ag, Cu, Al, Ti, In, Sn... |

| Jig Unit | Single or split DOME |

| Heater | Micro-sheath, Up to 350℃ |

| Vacuum Unit | Low Vacuum Pump + High Vacuum Pump + Polycold |

| Vacuum Controller | Vacuum Controller, Penning Gauge, Pirani Gauge |

| Coating Unit | Two sets of electron guns, Φ270mm oxygen-free copper crucible (12 hole type, ring type each set), one set of evaporation resistance source, Φ170mm caliber ion source |

| Charge Unit | MFC or APC Automatic pressure controller |

| Thickness Controller | IC-6 (INFICON) |

| Controller | Industrial PC + PLC + TP |

| Application | AR, UV/IR Cut filter, AF, Enhanced Reflection Coating, Decorative Coating, Band Pass Filter, RGB Filter, Photocatalyst, HR Coating, etc. |

| Remark: Customization | |

| Mode | HCEB-1100 |

| Size(mm) | Φ1100 x H1520 |

| Structure | Vertical Chamber with single Door, SUS304 Stainless Steel |

| Wavelength | 300nm~1100nm |

| Rotational speed | 0~60RPM (variable) |

| Pumping speed | Atmospheric pressure to 1.5×10-3Pa less than 30min |

| Ultimate vacuum | 8.0×10-5Pa |

| Coating material | Tio2, Ti3o5, H4, Zro2, Zns, Al2o3, Mgf2, Sio2, Au, Ag, Cu, Al, Ti, In, Sn... |

| Jig Unit | Single or split DOME |

| Heater | Micro-sheath, Up to 350℃ |

| Vacuum Unit | Low Vacuum Pump + High Vacuum Pump + Polycold |

| Vacuum Controller | Vacuum Controller, Penning Gauge, Pirani Gauge |

| Coating Unit | Two sets of electron guns, Φ270mm oxygen-free copper crucible (12 hole type, ring type each set), one set of evaporation resistance source, Φ170mm caliber ion source |

| Charge Unit | MFC or APC Automatic pressure controller |

| Thickness Controller | IC-6 (INFICON) |

| Controller | Industrial PC + PLC + TP |

| Application | AR, UV/IR Cut filter, AF, Enhanced Reflection Coating, Decorative Coating, Band Pass Filter, RGB Filter, Photocatalyst, HR Coating, etc. |

| Remark: Customization | |

| Mode | HCEB-1350 |

| Size(mm) | Φ1350 x H1610 |

| Structure | Vertical Chamber with single Door, SUS304 Stainless Steel |

| Wavelength | 300nm~1100nm |

| Rotational speed | 0~60RPM (variable) |

| Pumping speed | Atmospheric pressure to 1.5×10-3Pa less than 30min |

| Ultimate vacuum | 8.0×10-5Pa |

| Coating material | Tio2, Ti3o5, H4, Zro2, Zns, Al2o3, Mgf2, Sio2, Au, Ag, Cu, Al, Ti, In, Sn... |

| Jig Unit | Single or split DOME |

| Heater | Micro-sheath, Up to 350℃ |

| Vacuum Unit | Low Vacuum Pump + High Vacuum Pump + Polycold |

| Vacuum Controller | Vacuum Controller, Penning Gauge, Pirani Gauge |

| Coating Unit | Two sets of electron guns, Φ270mm oxygen-free copper crucible (12 hole type, ring type each set), one set of evaporation resistance source, Φ170mm caliber ion source |

| Charge Unit | MFC or APC Automatic pressure controller |

| Thickness Controller | IC-6 (INFICON) |

| Controller | Industrial PC + PLC + TP |

| Application | AR, UV/IR Cut filter, AF, Enhanced Reflection Coating, Decorative Coating, Band Pass Filter, RGB Filter, Photocatalyst, HR Coating, etc. |

| Remark: Customization | |

| Mode | HCEB-1550 |

| Size(mm) | Φ1550 x H1810 |

| Structure | Vertical Chamber with single Door, SUS304 Stainless Steel |

| Wavelength | 300nm~1100nm |

| Rotational speed | 0~60RPM (variable) |

| Pumping speed | Atmospheric pressure to 1.5×10-3Pa less than 30min |

| Ultimate vacuum | 8.0×10-5Pa |

| Coating material | Tio2, Ti3o5, H4, Zro2, Zns, Al2o3, Mgf2, Sio2, Au, Ag, Cu, Al, Ti, In, Sn... |

| Jig Unit | Single or split DOME |

| Heater | Micro-sheath, Up to 350℃ |

| Vacuum Unit | Low Vacuum Pump + High Vacuum Pump + Polycold |

| Vacuum Controller | Vacuum Controller, Penning Gauge, Pirani Gauge |

| Coating Unit | Two sets of electron guns, Φ270mm oxygen-free copper crucible (12 hole type, ring type each set), one set of evaporation resistance source, Φ170mm caliber ion source |

| Charge Unit | MFC or APC Automatic pressure controller |

| Thickness Controller | IC-6 (INFICON) |

| Controller | Industrial PC + PLC + TP |

| Application | AR, UV/IR Cut filter, AF, Enhanced Reflection Coating, Decorative Coating, Band Pass Filter, RGB Filter, Photocatalyst, HR Coating, etc. |

| Remark: Customization | |

| Mode | HCEB-1800 |

| Size(mm) | Φ1800 x H1900 |

| Structure | Vertical Chamber with single Door, SUS304 Stainless Steel |

| Wavelength | 300nm~1100nm |

| Rotational speed | 0~60RPM (variable) |

| Pumping speed | Atmospheric pressure to 1.5×10-3Pa less than 30min |

| Ultimate vacuum | 8.0×10-5Pa |

| Coating material | Tio2, Ti3o5, H4, Zro2, Zns, Al2o3, Mgf2, Sio2, Au, Ag, Cu, Al, Ti, In, Sn... |

| Jig Unit | Single or split DOME |

| Heater | Micro-sheath, Up to 350℃ |

| Vacuum Unit | Low Vacuum Pump + High Vacuum Pump + Polycold |

| Vacuum Controller | Vacuum Controller, Penning Gauge, Pirani Gauge |

| Coating Unit | Two sets of electron guns, Φ270mm oxygen-free copper crucible (12 hole type, ring type each set), one set of evaporation resistance source, Φ170mm caliber ion source |

| Charge Unit | MFC or APC Automatic pressure controller |

| Thickness Controller | IC-6 (INFICON) |

| Controller | Industrial PC + PLC + TP |

| Application | AR, UV/IR Cut filter, AF, Enhanced Reflection Coating, Decorative Coating, Band Pass Filter, RGB Filter, Photocatalyst, HR Coating, etc. |

| Remark: Customization | |

Looking for a solution tailored to your needs? Our team is ready to provide you with expert guidance and support.