AR film (substrate glass transmittance > 91.5%):

AS/AF membrane test standard:

Note: the test sample glass shall be the touch screen cover plate special glass after precision polishing, with smooth surface.

Key Features of Large E-beam Evaporation Optical Coating Machine

Meet the market demand of mass production

Multiple component combinations to meet customer needs

Easy to operate and maintain

High performance, high throughput

Automatic evaporation control system to realize automatic evaporation process

Provide factory remote diagnostics

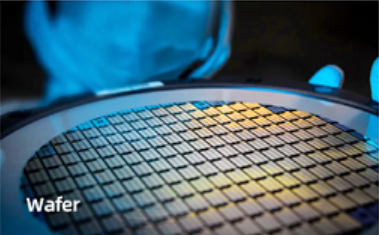

Equipped with electron gun, cavity type, waist type or ring crucible, impedance type evaporation source; equipped with optical film thickness controller or quartz crystal film thickness controller, it can realize automatic control of film forming speed and coating process; optional RF / Kaufman / hall type ion source.

The development of the series is to meet the market demand for large-scale production. The machine has been verified by production, with high productivity and the lowest cost of ownership. The cost of mass optical elements is optimized. AR, UV / IR cut-off filter, AF, hard film, decorative film, ITO film, band-pass filter, HR film can be prepared.

| Mode | HCEB-2700 |

| Size(mm) | Φ2700 x H1850 |

| Structure | Vertical Chamber with single Door, SUS304 Stainless Steel |

| Wavelength | 380nm~780nm |

| Rotational speed | 0~30RPM (variable) |

| Pumping speed | Atmospheric pressure to 2.0×10-3Pa less than 30min |

| Ultimate vacuum | 8.0×10-5Pa |

| Coating material | Tio2,Ti3o5,H4,Zro2,Zns,Al2o3,Mgf2,Sio2,Au,Ag,Cu,Al,Ti,In,Sn... |

| Jig Unit | Single or split DOME |

| Heater | Micro-sheath, Up to 250℃ |

| Vacuum Unit | Low Vacuum Pump + High Vacuum Pump + Polycold |

| Vacuum Controller | Vacuum Controller, Penning Gauge, Pirani Gauge |

| Coating Unit | E-type E-Beam Source(270°Deflection) with Hole-shape, Waist-shape or Annular Crucibles &. 10KW Power Supply.Thermal Source Available. RF / Kauffman-type I-beam / End-hall-type Source. |

| Charge Unit | MFC or APC Automatic pressure controller |

| Thickness Controller | Crystal Control or Optical Control |

| Controller | Industrial PC + PLC + TP |

| Application | AR, UV/IR Cut Filter, AF, Hard Coating, Decorative Coating, ITO Coating, Band Pass Filter, HR Coating, etc. |

| Remark: Customization | |

| Mode | HCEB-2350 |

| Size(mm) | Φ2350 x H1510 |

| Structure | Vertical Chamber with single Door, SUS304 Stainless Steel |

| Wavelength | 380nm~780nm |

| Rotational speed | 0~30RPM (variable) |

| Pumping speed | Atmospheric pressure to 2.0×10-3Pa less than 30min |

| Ultimate vacuum | 8.0×10-5Pa |

| Coating material | Tio2,Ti3o5,H4,Zro2,Zns,Al2o3,Mgf2,Sio2,Au,Ag,Cu,Al,Ti,In,Sn... |

| Jig Unit | Single or split DOME |

| Heater | Micro-sheath, Up to 250℃ |

| Vacuum Unit | Low Vacuum Pump + High Vacuum Pump + Polycold |

| Vacuum Controller | Vacuum Controller, Penning Gauge, Pirani Gauge |

| Coating Unit | E-type E-Beam Source(270°Deflection) with Hole-shape, Waist-shape or Annular Crucibles &. 10KW Power Supply.Thermal Source Available. RF / Kauffman-type I-beam / End-hall-type Source. |

| Charge Unit | MFC or APC Automatic pressure controller |

| Thickness Controller | Crystal Control or Optical Control |

| Controller | Industrial PC + PLC + TP |

| Application | AR, UV/IR Cut Filter, AF, Hard Coating, Decorative Coating, ITO Coating, Band Pass Filter, HR Coating, etc. |

| Remark: Customization | |

Looking for a solution tailored to your needs? Our team is ready to provide you with expert guidance and support.