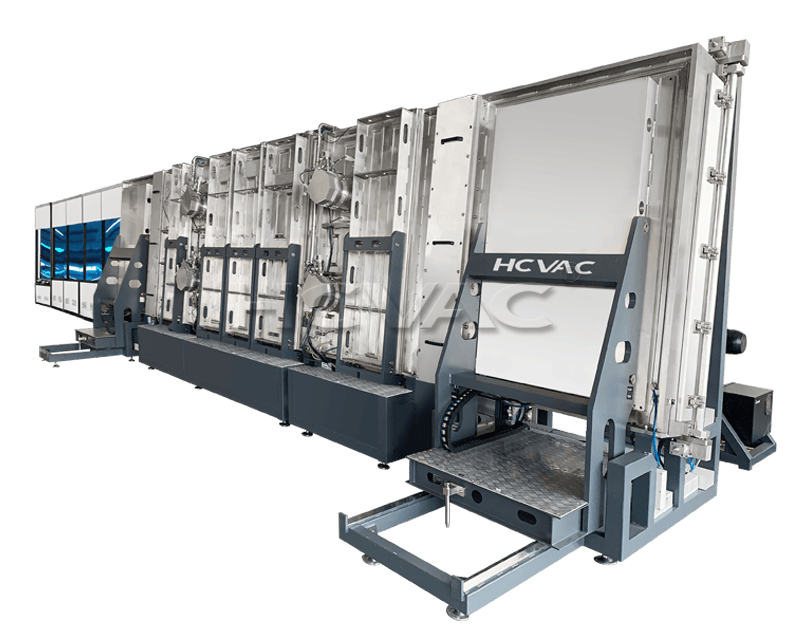

The machine combines magnetron sputtering, cathodic arc ion coating, and a uniquely designed ion source-assisted deposition technology. It is suitable for applying decorative and anti-corrosion coatings on both sides of metal plates, enhancing their appearance and surface properties

Decorative Coatings

◆ Create surfaces with a premium metallic appearance at minimal processing cost. A wide range of colors can be achieved through surface coloring or interference layers.

Anti-Corrosion Coatings

◆ PVD technology is used to deposit zinc or magnesium on both sides of the steel strip, significantly enhancing corrosion resistance.

Key Features of Decorative Metal Plates Inline Coating System

The film is dense, uniform, and has excellent adhesion.

High deposition efficiency and fast coating speed

Multi color, uniform and bright surface

Accurate parameter control, automatic control and repeatable coating process

Flexible combination of multiple system technologies

Provide factory remote diagnostics

The modular design concept allows for flexible integration of the strip correction system, plasma pretreatment, magnetron sputtering system, on-line measurement and process control system, and electron beam evaporation. High-stability magnetron power supplies and high-precision gas mass flow meters ensure consistent coating parameters, uniform film quality, high deposition efficiency, fast coating speed, and strong adhesion.

The design includes seven vacuum chambers: the inlet chamber, inlet buffer chamber, import transfer chamber, process chamber, outlet transfer chamber, outlet buffer chamber, and outlet chamber. The production line uses advanced molecular pump technology for atmospheric isolation and incorporates a turbo floating molecular pump to achieve efficient isolation, stable pumping speed, and uniform gas distribution.

| Item | Performance |

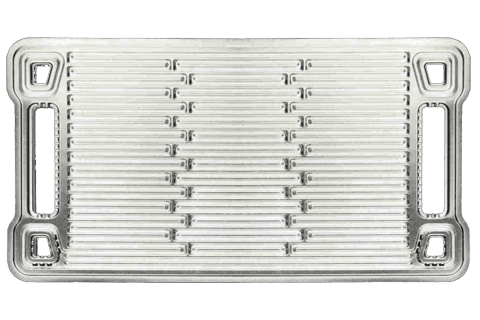

| Substrate | Flat stainless steel plate |

| Size | Width 1250mm, length ≤3400mm, thickness 0.5-3mm |

| Coating technology | Multi arc ion plating, medium frequency magnetron sputtering |

| Rhythm | ~60s(Customized according to customer needs) |

| Dynamic rate | ≥90% |

| Color scheme | Material intrinsic color + interference color |

| Film thickness uniformity | Multi arc ion plating ≤10% Medium frequency magnetron sputtering ≤2% |

Looking for a solution tailored to your needs? Our team is ready to provide you with expert guidance and support.