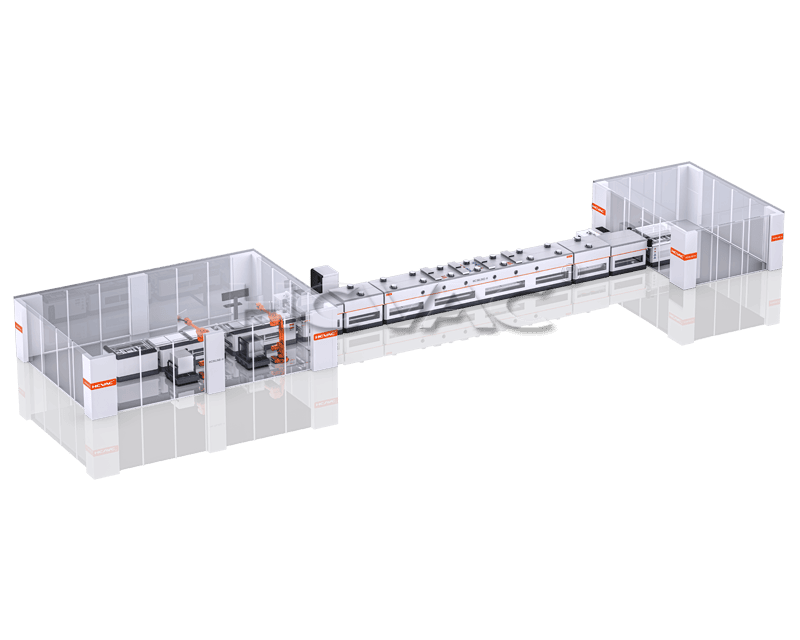

This coating line is specially designed for solar cells, ideal for depositing transparent conductive films used as anti-reflection layers and transparent electrodes. It effectively improves solar energy conversion efficiency, reduces manufacturing costs, and features non-toxic, environmentally friendly, and stable film performance.

Compared with traditional vertical coating methods, this system overcomes limitations in mass production by enabling large-scale continuous processing, significantly increasing production capacity and efficiency.

It helps solar module manufacturers achieve higher yield, lower operating costs, and stronger market competitiveness.

Key Features of Solar Cell Inline Coating System

Mature magnetron sputtering technology

Design of vacuum chamber with separate space

Flexible configuration of carrier transmission system

Reliable heating control system

Low cost and high productivity

Flexible dynamic design

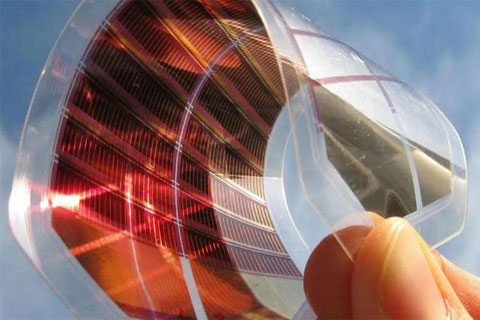

The machine adopts large-area sputtering technology with a wide coating width, allowing simultaneous processing of multiple substrates. It is especially suitable for applications requiring ultra-low cost and high productivity. The system is also adaptable for smaller or ultra-thin substrates.

Thanks to its modular design, the coating line can be equipped with rotating magnetrons for sputtering high-performance transparent conductive oxide films or various other materials, such as metals and metal oxides. Substrates can be pretreated either in vacuum or before entering the vacuum chamber—for example, through cleaning or etching.

| Item | Performance |

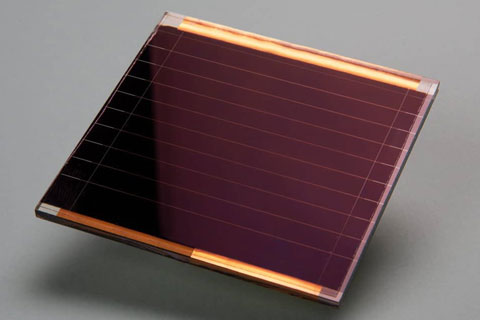

| Applicable substrate | M2、M4 silicon wafer |

| Substrate temperature | <150℃ |

| Properties of ITO Films | Transmittance>90% Resistivity<4 × 10-4 Ω · cm |

| Film uniformity | ≤±5% |

| Rhythm | 40~60s |

| Dynamic rate | ≥90% |

| Capacity | 5000~8000 pcs/hour |

| Item | Performance |

| Applicable substrate | M2、M4 silicon wafer |

| Substrate temperature | <150℃ |

| Film uniformity | ≤±5% |

| Rhythm | 40~60s |

| Dynamic rate | ≥90% |

| Capacity | 5000~8000 pcs/hour |

| Item | Performance |

| Applicable substrate | M2、M4 silicon wafer |

| Substrate temperature | <150℃ |

| Film uniformity | ≤±5% |

| Rhythm | 40~60s |

| Dynamic rate | ≥90% |

| Capacity | 5000~8000 pcs/hour |

Looking for a solution tailored to your needs? Our team is ready to provide you with expert guidance and support.