Capabilities:

1. Single / Double / Triple Silver Low-E Coatings

For energy-efficient windows, curtain walls, and facades

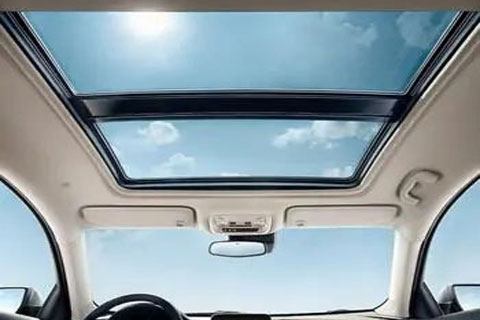

2. Solar-Control Coatings

For automotive windshields, sunroofs, and architectural glass

3. Anti-Reflective (AR) Coatings

For photovoltaic modules, displays, and BIPV glass

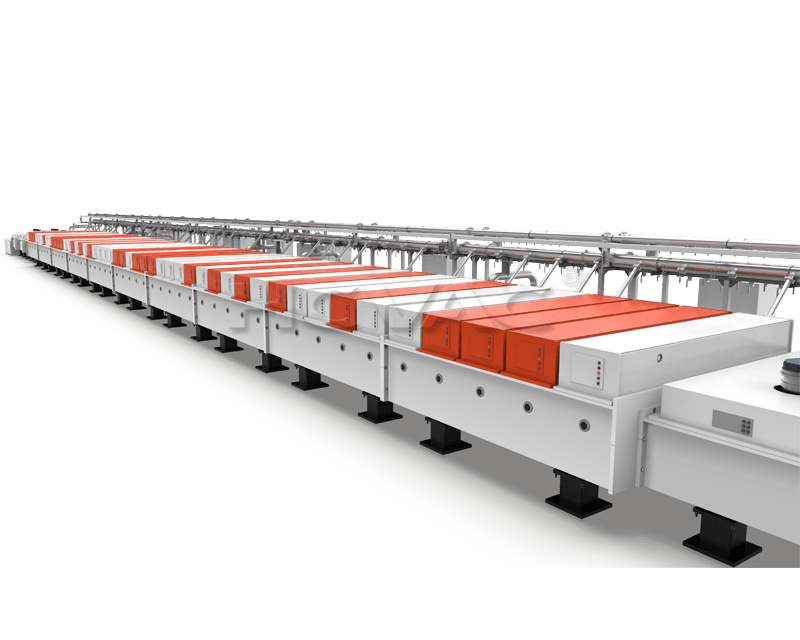

Our Low-E Glass Coating Machine is engineered for the high-efficiency production of Low-E coated glass, solar-control glass, and anti-reflective (AR) film.

Designed with advanced magnetron sputtering technology, this vacuum coating system delivers superior optical and thermal performance across a wide range of glass applications.

Substrate Size: Max. 3300 × 6000 mm (customizable up to 24000 mm for ultra-large glass panels)

Substrate Thickness: 3–19 mm (customizable)

Boost your glass performance with our industry-leading Low-E Glass Coating Machine

Key Features of Magnetron Sputtering Low-E Glass Coating Machine

Save material and maintenance time, resulting in maximum utilization

Stable process and excellent gas separation

High splash rate, low oxidation rate and low gas consumption

High uptime and fast maintenance cycle

Flexible programmable logic controller

Allows configuration according to individual production needs

| Glass specifications | |

| Dimensions of plated glass | Size |

| Standard | Max.3300*6000mm |

| Super long (Dual-Chamber Linked) | 3300*12000mm |

| Super long (Triple-Chamber Linked) | 3300*18000mm |

| Thickness of plating glass | 2-19mm |

| Production cycle | |

| Cycle time | > 30 seconds (varies by coating structure) |

| Ultimate Vacuum | < 2 × 10⁻⁶ mbar |

| Super long glass coating season | 240s |

| Annual capacity | 1.8-8 million square meters |

| Note: the design can be optimized according to the specific requirements of customers and the specific conditions of each region, and the cost, energy consumption and production efficiency can be considered to the greatest extent for users. | |

Looking for a solution tailored to your needs? Our team is ready to provide you with expert guidance and support.