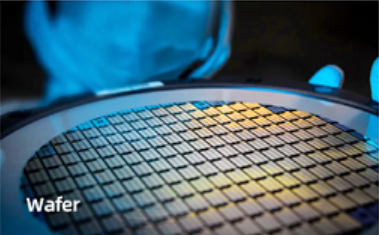

The machine is designed for coating photomask substrates of semiconductor chips and EMI packages. It is equipped with degassing, plasma treatment, sputtering, and other modules. With a standardized and modular design concept, it offers high customization to meet product specifications while keeping investment costs low. Key components use imported accessories to ensure the machine's stability.

Application:

Key Features of Semiconductor Chip Inline Coating System

Wider choice of substrates

Uniform deposition rate in the whole chamber

Excellent surface control of substrate temperature

Flexible combination of various technologies

Considering product specification and low investment cost

Provide factory remote diagnostics

| Item | Performance |

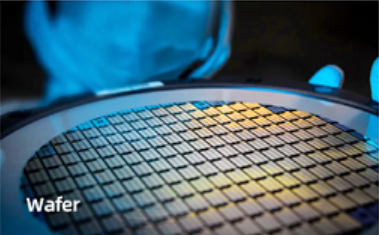

| Substrate | Glass |

| Workpiece size | According to customer demand |

| Pallet size | 1400mm×800mm |

| Rhythm | Customized according to customer needs |

| Film material | Si, Cr and their compounds |

| Film uniformity | ≤±2% |

| Dynamic rate | ≥90% |

Item | Performance |

| Types of film making | EMI anti electromagnetic interference shielding film, decorative film, etc |

| Power supply type | DC magnetic control power supply + high voltage ion bombardment power supply |

| Cylindrical target | DC magnetron target (oxygen free copper target + stainless steel target) |

| vacuum system | Mechanical pump + roots pump + diffusion pump + maintenance pump (or optional: molecular pump, cryogenic system) |

| Inflation system | Mass flow controller (1-3 channels) |

| Ultimate vacuum | 6×10-4 pa(no-loading,clean chamber) |

| Pumping time | No-loading from air to 5×10-3pa <6mins |

| Control mould | Manual/Automatic all-in-one mode, Touching screen+PLC |

| Remark | We can design the dimension of the vacuum chamber according to customer’s demand |

Looking for a solution tailored to your needs? Our team is ready to provide you with expert guidance and support.