This coating lines are mainly used for plate glass, acrylic, PC, PET substrates, various metal films, dielectric films, dielectric metal composite films, transparent conductive films, CF films, etc.

It is suitable for the surface coating of plastic panel and glass display screen in mobile phone, electronics, household appliances and other industries.

Our company can provide design, complete set of machine, process and "turnkey" engineering service.

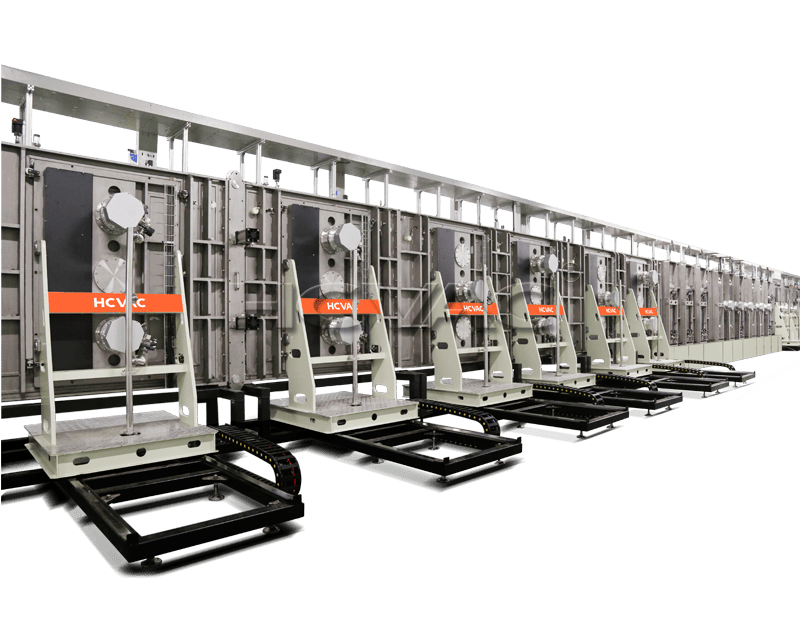

Key Features of Multifunctional Vertical Continuous Inline Coating System For Display

Vertical system configuration, the lowest particle collision

Excellent surface control of substrate temperature

Fully open the vertical chamber on the track system

Good accessibility, fast maintenance

Design and use of high precision and special target materials

Suitable for any application in large area coating field

The material of vacuum chamber body is SUS304. The wall of vacuum chamber is polished, and the outer wall is treated with spray bead after polishing. The vacuum chamber is separated by independent gate valve - plug valve, which can realize effective isolation and stabilize process gas.

At present, our company adopts the gate valve design, which has better sealing effect and more durable than general flap valve. The transmission adopts magnetic guidance to ensure the stability of transmission.

The speed of each section of the whole production line is driven by frequency conversion motor, and the running speed is adjustable; electrical control system: touch screen and PLC automatic control, man-machine dialogue to achieve the system data display, operation and control.

| Substrate | Flat / curved glass |

| Substrate size | G2.5~G8.5 |

| Rhythm | ~60s(Customized according to customer needs) |

| Dynamic rate | ≥ 90% |

| Coating material | SiO2/SiNx/Nb2O5/TiO2 |

| Single target uniformity | ≤±2% |

| Optical performance | Tavg of 4AR >95% |

| Tavg of 6AR >95.5% | |

| (The transmittance of glass substrate is 91.5%, and the average value is 400-700nm) | |

| Color difference value | Plane glass ∆E<1 |

| Curved glass ∆E<3 |

| Substrate | PI film /0.06mm thick |

| Substrate size | G2.5~G8.5 |

| Rhythm | ~60s(Customized according to customer needs) |

| Fold test | 80000-100000 times |

| Dynamic rate | ≥ 90% |

| Coating material | SiO2/SiNx/Nb2O5/TiO2 /AF |

| Single target uniformity | ≤±2% |

Looking for a solution tailored to your needs? Our team is ready to provide you with expert guidance and support.