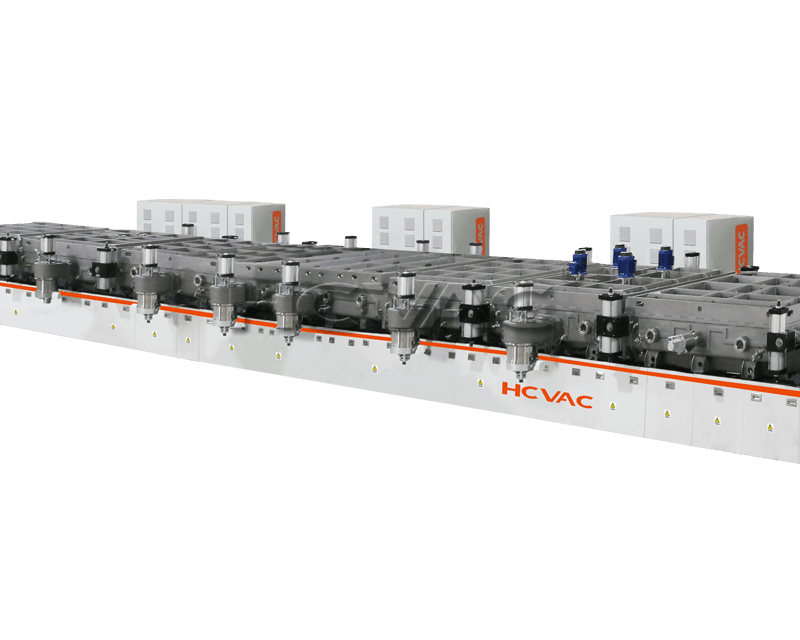

We focus on designing and manufacturing glass mirror production lines, including silver mirror production lines, aluminum mirror production lines, and colored mirror production lines. Our technology is based on vacuum coating production lines and magnetron sputtering coating machines, which guarantee excellent coating quality, high efficiency, and long-lasting mirrors.

By choosing us, you get a trusted partner for advanced mirror production technology and turnkey glass mirror manufacturing solutions.

Key Features of Large Area Mirror Inline Coating System

The film is compact, uniform and has strong adhesion

High deposition efficiency and fast coating speed

Up to 99% light reflection

Accurate parameter control, automatic control and repeatable coating process

Flexible combination of multiple system technologies

Provide factory remote diagnostics

| Item | Performance |

| Power supply | Resistance heating tungsten wire evaporation transformer power supply, high voltage ion bombardment power supply, silicon controlled rectifier power supply |

| Vacuum system | Mechanical pump + roots pump + diffusion pump + maintenance pump (or option: cryogenic system) |

| Ultimate vacuum | 8×10-4 pa(no-loading,clean chamber) |

| Pumping time | No-loading from air to 5×10-2pa <6mins |

| Control mould | Manual/Automatic all-in-one mode, Touching screen+PLC |

| Remark | We can design the dimension of the vacuum chamber according to customer’s demand |

Looking for a solution tailored to your needs? Our team is ready to provide you with expert guidance and support.